Your location:

Product classification of Meiyan One Pump Valve

- ShangHai Meiyan Yi Pump & Valve Co.,LTD.

- Sales hotline:

+86 21 5640 2009 - Pump customer service:

+86 138 1691 3072 - Valve customer service:

+86 1381 6913 072 - E-mail:

my1pv@1bengfa.com

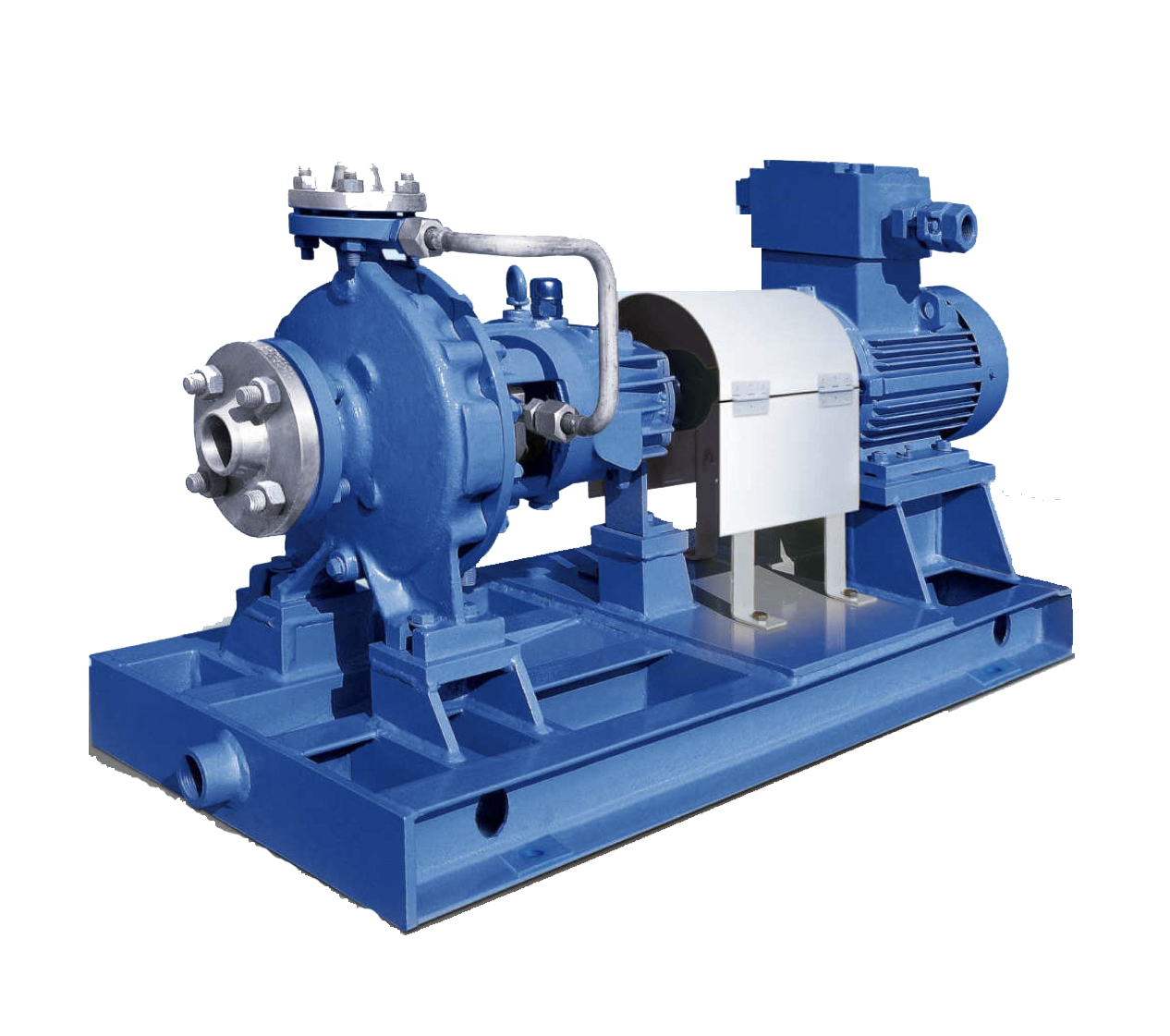

GDL multi-stage pipeline centrifugal pump

- Brand:YI PUMP VALVE

- Type:GDL、GDL-B、GDLS、GDLS-B

- PN/H:28.5~230m

- Heat:-15℃~+120℃

- Connection Type:flange

- Product Name:GDL multi-stage pipeline centrifugal pump

- Diameter:1.4~192T/h

- Material:Cast iron, stainless steel SS304、SS304L、SS316、SS316L

- Driven Mode:Electric, multi-stage

- Applicable Scope:Suitable for transporting clean water or liquids with physical and chemical properties similar to clean water.

- Product Overview

- Performance Data

- Size Weight

GDL multi-stage pipeline centrifugal pump

overview

The GDL type vertical single suction multi-stage segmented pipeline centrifugal pump is a new generation of water pump product designed and manufactured by our unit in recent years based on excellent pump types at home and abroad, combined with user requirements and relevant fire safety standards, and in accordance with JB/TQ6435-92 standards.

The GDL type multi-stage pipeline centrifugal pump adopts a vertical segmented external stainless steel shell structure, which enables the inlet and outlet of the pump to be located on the same horizontal line and have the same diameter, and can be installed in the pipeline like a valve. It also concentrates the high pressure of the multi-stage pump, has the advantages of small footprint of the vertical pump and convenient installation of the pipeline pump. At the same time, due to the excellent hydraulic model used, it also has the advantages of high efficiency, energy saving, and smooth operation. The shaft seal adopts wear-resistant mechanical seal, with no leakage and long service life.

In order to better meet the requirements of users, our unit has also developed the GDLS type with the outlet located at the upper part. Its inlet and outlet can be installed at different relative positions (0 °, 90 °, 180 °), making it extremely convenient to use.

In order to provide users with safer and more reliable use of this type of pump, Shanghai Meiyanyi Pump Valve has specially developed a detachable structural type. In addition to all the advantages of GDL and GDLS, it also provides a more convenient, fast, and labor-saving way for you to replace vulnerable parts such as mechanical seals, making this type of pump more worry free to operate and maintain.

Application scope

The GDL type multi-stage pipeline centrifugal pump is mainly suitable for the circulation and pressurization of cold and hot water in high-pressure operating systems, parallel water supply of multiple pumps in high-rise buildings, fire protection, boiler feedwater and cooling water systems, and the transportation of various flushing liquids.

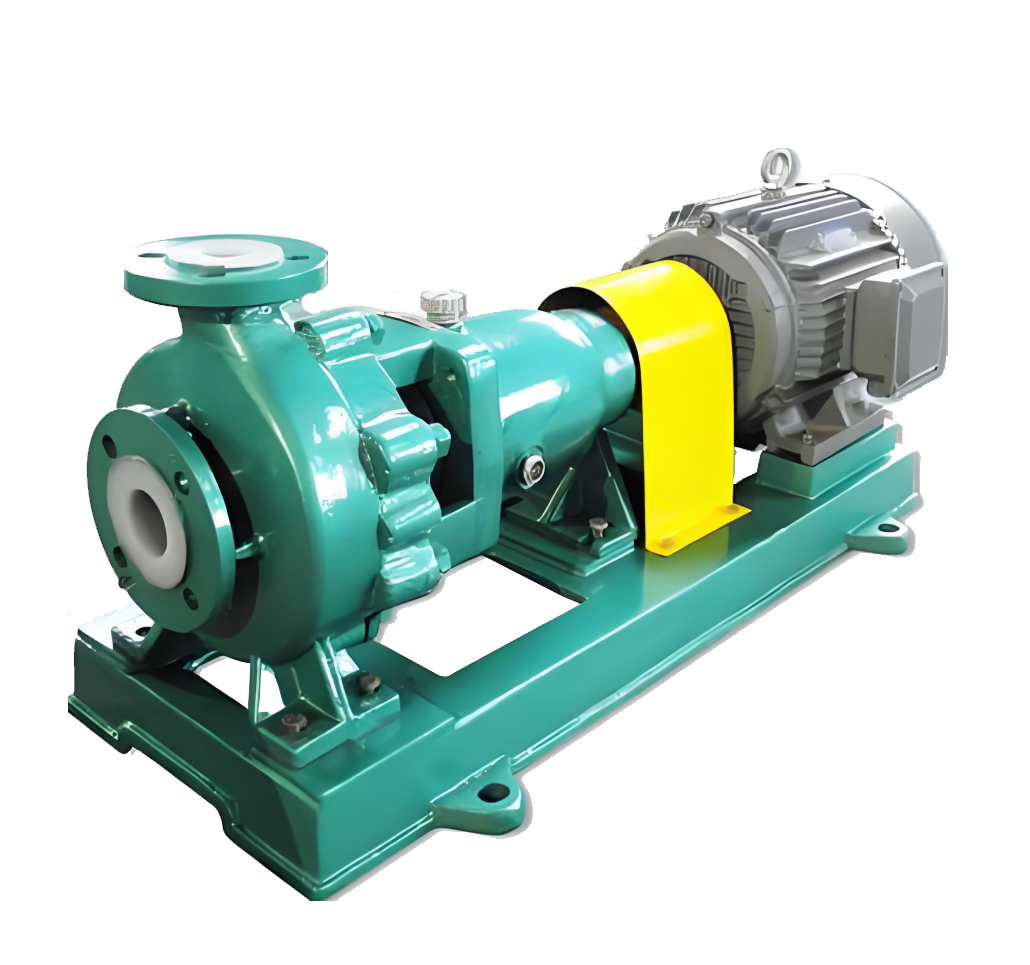

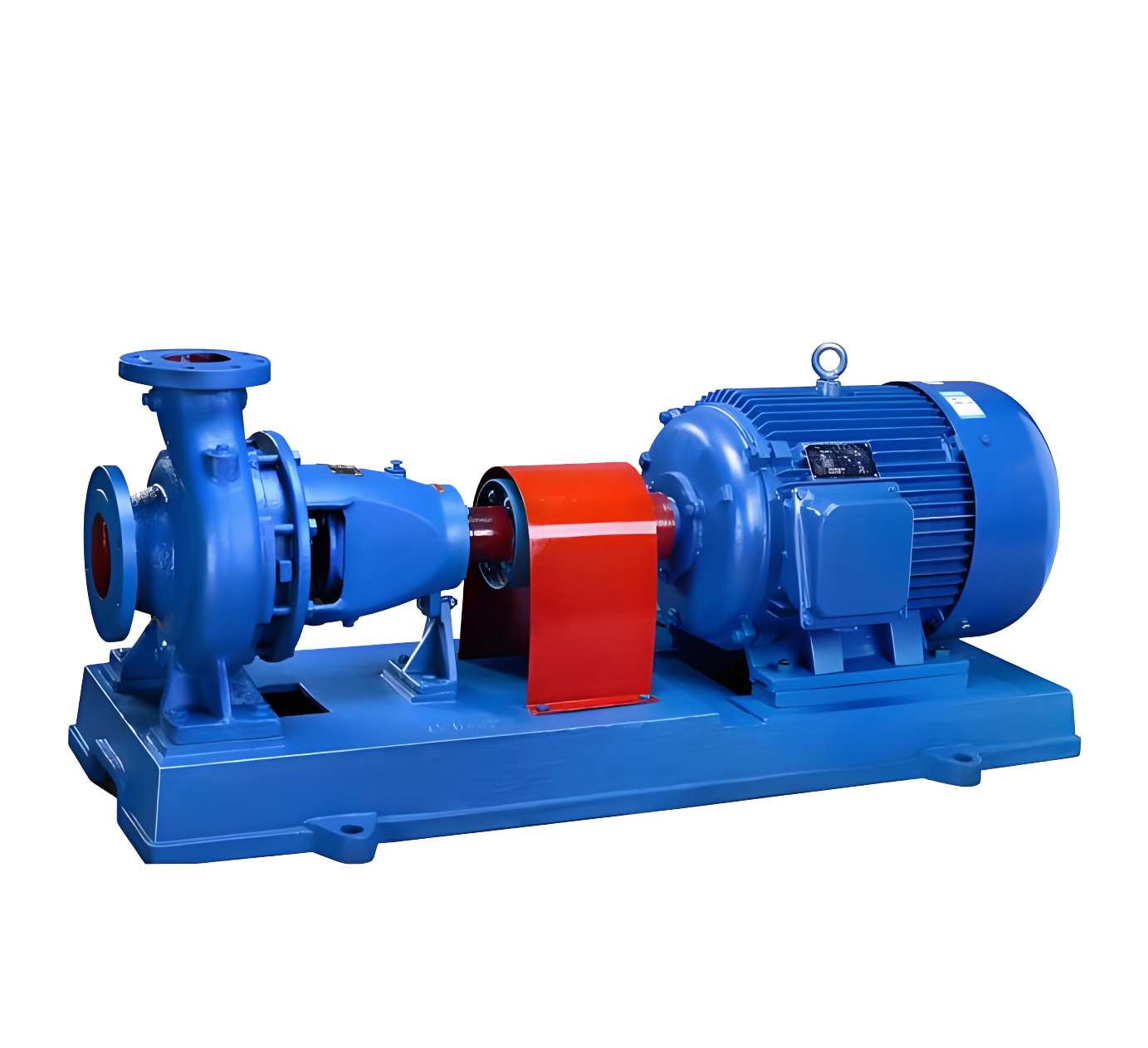

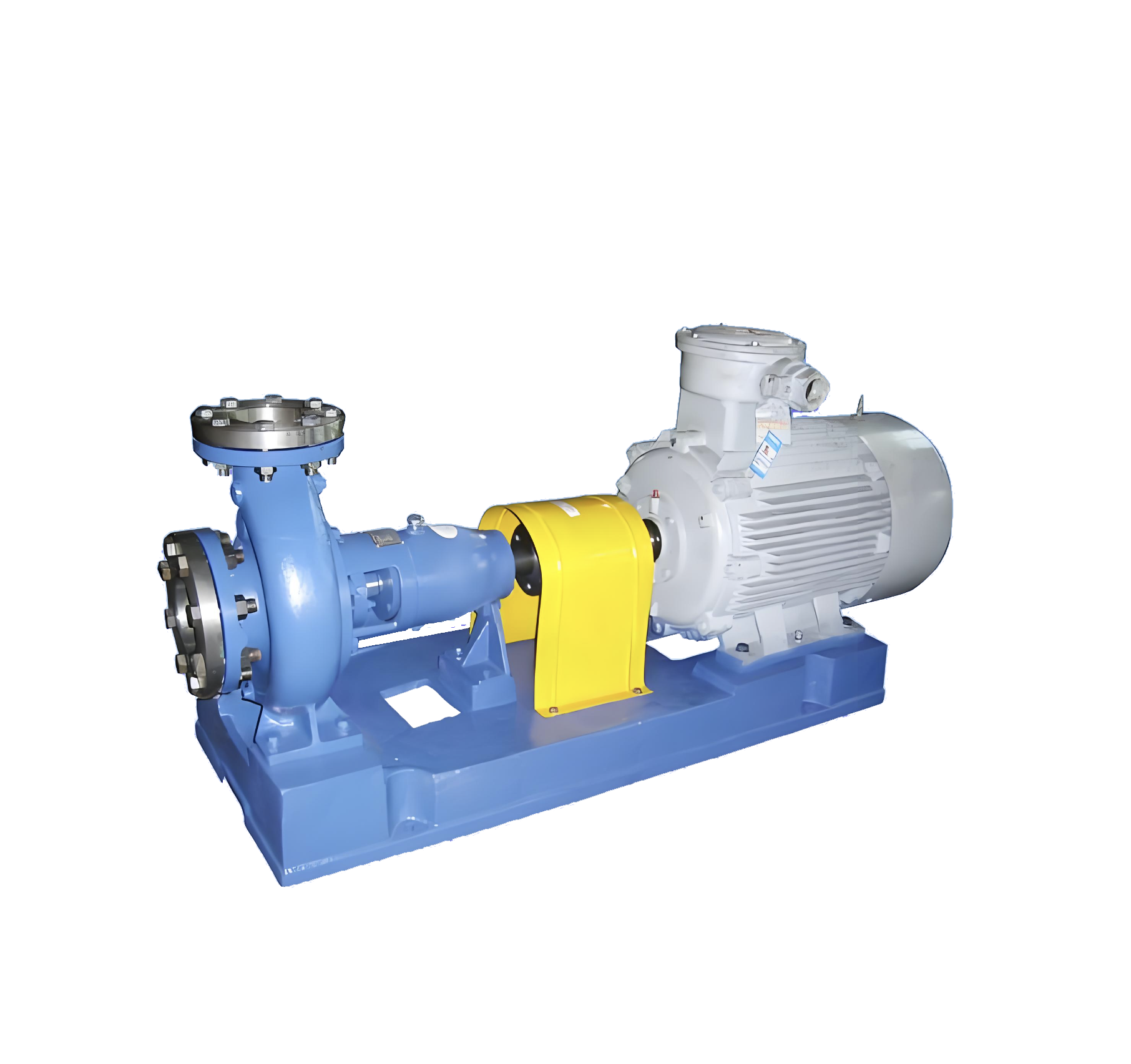

Product diagram of GDL multi-stage pipeline centrifugal pump

working conditions

1. This type of pump can transport clean water or liquids with physical and chemical properties similar to clean water;

2. Liquid temperature:- 15℃~+120℃;

3. Working pressure: The maximum working pressure is less than 2.5Mpa, which means that the system pressure is equal to the inlet pressure plus the pressure when the valve is closed, which is less than 2.5Mpa;

4. The temperature of the surrounding environment should be below 40 ℃, and the relative humidity should not exceed 95%;

5. When transporting corrosive media and hot liquids, please specify at the time of ordering so that special materials can be used to meet the usage requirements.

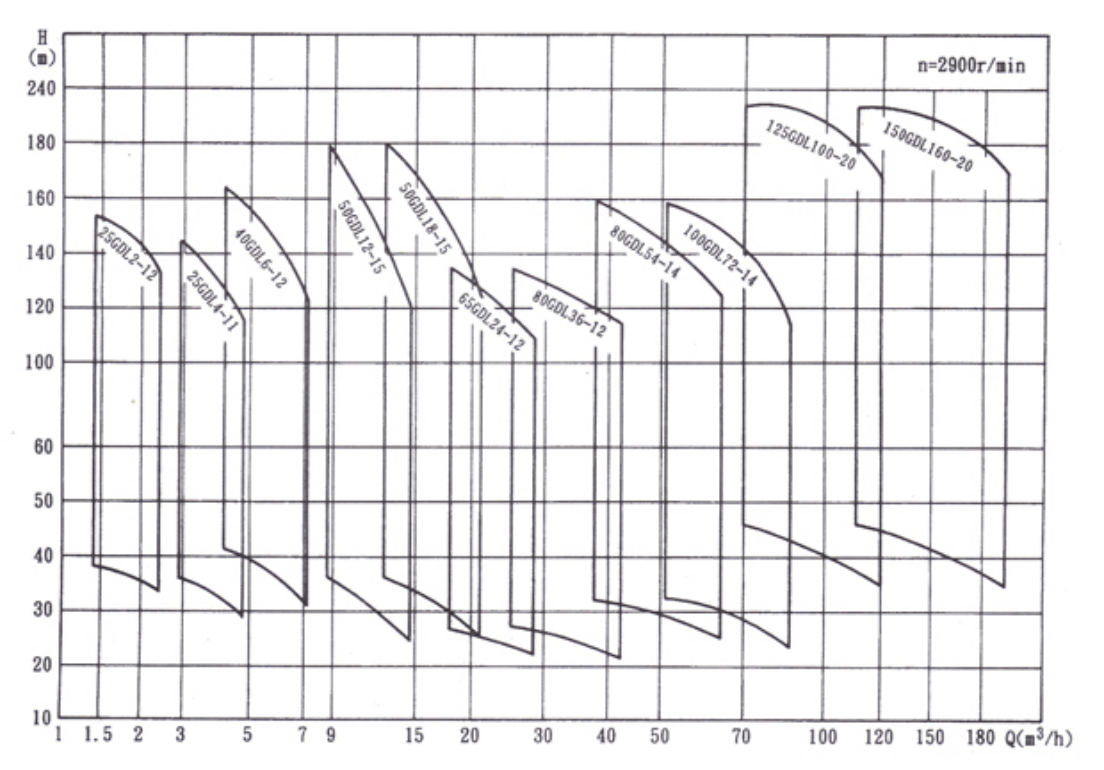

GDL multi-stage pipeline centrifugal pump

GDL multi-stage pipeline centrifugal pump

Spectrogram

Note: The spectra of GDL-B, GDLS, and GDLS-B types are the same as the above figure

Model and Performance Parameter Table

| 型号model | 流量internet traffic | 扬程lift | 效率efficiency | 转速rotational speed | 功率powerKW | 汽蚀余量m | 进出口径mm | 高度Hmm | 重量kg | 高度h1mm | ||

| m3/h | L/S | m | % | r/min | 轴功率 | 电机功率 | ||||||

| 25GDL2-12×3 | 1.422.4 | 0.390.560.67 | 383633 | 233032 | 2900 | 0.630.650.67 | 1.1 | 1.41.71.8 | 25 | 606 | 58 | 125 |

| 25GDL2-12×4 | 1.422.4 | 0.390.560.67 | 504844 | 233032 | 2900 | 0.830.870.90 | 1.1 | 1.41.71.8 | 25 | 646 | 62 | 165 |

| 25GDL2-12×5 | 1.422.4 | 0.390.560.67 | 636055 | 233032 | 2900 | 1.041.091.12 | 1.5 | 1.41.71.8 | 25 | 711 | 68 | 205 |

| 25GDL2-12×6 | 1.422.4 | 0.390.560.67 | 767266 | 233032 | 2900 | 1.261.301.35 | 1.5 | 1.41.71.8 | 25 | 751 | 72 | 245 |

| 25GDL2-12×7 | 1.422.4 | 0.390.560.67 | 888477 | 233032 | 2900 | 1.461.521.57 | 2.2 | 1.41.71.8 | 25 | 816 | 78 | 285 |

| 25GDL2-12×8 | 1.422.4 | 0.390.560.67 | 1019688 | 233032 | 2900 | 1.631.741.80 | 2.2 | 1.41.71.8 | 25 | 856 | 82 | 325 |

| 25GDL2-12×9 | 1.422.4 | 0.390.560.67 | 11410899 | 233032 | 2900 | 1.891.962.02 | 2.2 | 1.41.71.8 | 25 | 896 | 86 | 365 |

| 25GDL2-12×10 | 1.422.4 | 0.390.560.67 | 126120110 | 233032 | 2900 | 2.012.172.24 | 3 | 1.41.71.8 | 25 | 981 | 98 | 405 |

| 25GDL2-12×11 | 1.422.4 | 0.390.560.67 | 139132121 | 233032 | 2900 | 2.312.392.47 | 3 | 1.41.71.8 | 25 | 1021 | 102 | 445 |

| 25GDL2-12×12 | 1.422.4 | 0.390.560.67 | 152144132 | 233032 | 2900 | 2.522.612.70 | 3 | 1.41.71.8 | 25 | 1061 | 106 | 485 |

| 25GDL4-11×3 | 2.844.8 | 0.781.111.33 | 363328.5 | 324041 | 2900 | 0.860.900.91 | 1.1 | 1.41.71.8 | 25 | 606 | 58 | 125 |

| 25GDL4-11×4 | 2.844.8 | 0.781.111.33 | 484438 | 324041 | 2900 | 1.141.201.21 | 1.5 | 1.41.71.8 | 25 | 671 | 65 | 165 |

| 25GDL4-11×5 | 2.844.8 | 0.781.111.33 | 605547.5 | 324041 | 2900 | 1.431.501.51 | 2.2 | 1.41.71.8 | 25 | 736 | 72 | 205 |

| 25GDL4-11×6 | 2.844.8 | 0.781.111.33 | 726657 | 324041 | 2900 | 1.721.801.82 | 2.2 | 1.41.71.8 | 25 | 776 | 76 | 245 |

| 25GDL4-11×7 | 2.844.8 | 0.781.111.33 | 847766.5 | 324041 | 2900 | 2.002.102.12 | 3 | 1.41.71.8 | 25 | 861 | 86 | 285 |

| 25GDL4-11×8 | 2.844.8 | 0.781.111.33 | 968876 | 324041 | 2900 | 2.292.402.42 | 3 | 1.41.71.8 | 25 | 901 | 90 | 325 |

| 25GDL4-11×9 | 2.844.8 | 0.781.111.33 | 1089985.5 | 324041 | 2900 | 2.572.702.73 | 3 | 1.41.71.8 | 25 | 941 | 94 | 365 |

| 25GDL4-11×10 | 2.844.8 | 0.781.111.33 | 12011095 | 324041 | 2900 | 2.863.003.03 | 4 | 1.41.71.8 | 25 | 1011 | 110 | 405 |

| 25GDL4-11×11 | 2.844.8 | 0.781.111.33 | 132121104.5 | 324041 | 2900 | 3.143.303.33 | 4 | 1.41.71.8 | 25 | 1051 | 114 | 445 |

| 25GDL4-11×12 | 2.844.8 | 0.781.111.33 | 144132114 | 324041 | 2900 | 3.433.603.64 | 4 | 1.41.71.8 | 25 | 1091 | 118 | 485 |

| 25GDL4-11×13 | 2.844.8 | 0.781.111.33 | 156143123.5 | 324041 | 2900 | 3.723.903.94 | 4 | 1.41.71.8 | 25 | 1131 | 122 | 525 |

Note: 1. GDLS, GDL-B, and GDLS-B models have the same performance parameters as GDL models except for slight differences in weight and H size. 2. The h1 size is only used for GDLS and GDLS-B models.

Model and Performance Parameter Table2

| 型号 | 流量 | 扬程 | 效率 | 转速 | 功率KW | 汽蚀余量m | 进出口径mm | 高度Hmm | 重量kg | 高度h1mm | ||

| m3/h | L/S | m | % | r/min | 轴功率 | 电机功率 | ||||||

| 40GDL6-12×3 | 4.267.2 | 1.171.672.0 | 413630.5 | 435252 | 2900 | 1.091.131.15 | 1.5 | 1.41.71.8 | 40 | 657 | 72 | 125 |

| 40GDL6-12×4 | 4.267.2 | 1.171.672.0 | 544840.6 | 435252 | 2900 | 1.451.51.53 | 2.2 | 1.41.71.8 | 40 | 722 | 78 | 165 |

| 40GDL6-12×5 | 4.267.2 | 1.171.672.0 | 686051 | 435252 | 2900 | 1.811.881.92 | 2.2 | 1.41.71.8 | 40 | 762 | 82 | 205 |

| 40GDL6-12×6 | 4.267.2 | 1.171.672.0 | 827261 | 435252 | 2900 | 2.182.262.30 | 3 | 1.41.71.8 | 40 | 847 | 92 | 245 |

| 40GDL6-12×7 | 4.267.2 | 1.171.672.0 | 958471 | 435252 | 2900 | 2.542.642.69 | 3 | 1.41.71.8 | 40 | 887 | 96 | 285 |

| 40GDL6-12×8 | 4.267.2 | 1.171.672.0 | 1099681 | 435252 | 2900 | 2.913.013.07 | 4 | 1.41.71.8 | 40 | 967 | 112 | 325 |

| 40GDL6-12×9 | 4.267.2 | 1.171.672.0 | 12310891 | 435252 | 2900 | 2.273.393.45 | 4 | 1.41.71.8 | 40 | 1007 | 116 | 365 |

| 40GDL6-12×10 | 4.267.2 | 1.171.672.0 | 136120102 | 435252 | 2900 | 3.363.773.84 | 4 | 1.41.71.8 | 40 | 1047 | 120 | 405 |

| 40GDL6-12×11 | 4.267.2 | 1.171.672.0 | 150132112 | 435252 | 2900 | 4.04.154.22 | 5.5 | 1.41.71.8 | 40 | 1132 | 140 | 445 |

| 40GDL6-12×12 | 4.267.2 | 1.171.672.0 | 164144122 | 435252 | 2900 | 4.364.524.60 | 5.5 | 1.41.71.8 | 40 | 1172 | 146 | 485 |

| 50GDL12-15×2 | 8.41214.4 | 2.333.334.0 | 363024 | 485653 | 2900 | 1.721.751.85 | 2.2 | 1.41.81.8 | 50 | 766 | 113 | 158 |

| 50GDL12-15×3 | 8.41214.4 | 2.333.334.0 | 544536 | 485653 | 2900 | 2.572.632.78 | 3 | 1.41.81.8 | 50 | 866 | 129 | 233 |

| 50GDL12-15×4 | 8.41214.4 | 2.333.334.0 | 726048 | 485653 | 2900 | 3.433.53.70 | 4 | 1.41.81.8 | 50 | 1001 | 149 | 308 |

| 50GDL12-15×5 | 8.41214.4 | 2.333.334.0 | 907560 | 485653 | 2900 | 4.24.274.63 | 5.5 | 1.41.81.8 | 50 | 1126 | 181 | 383 |

| 50GDL12-15×6 | 8.41214.4 | 2.333.334.0 | 1089072 | 485653 | 2900 | 5.155.255.55 | 5.5 | 1.41.81.8 | 50 | 1201 | 190 | 458 |

| 50GDL12-15×7 | 8.41214.4 | 2.333.334.0 | 12610584 | 485653 | 2900 | 6.06.126.48 | 7.5 | 1.41.81.8 | 50 | 1276 | 204 | 533 |

| 50GDL12-15×8 | 8.41214.4 | 2.333.334.0 | 14412096 | 485653 | 2900 | 6.867.07.40 | 7.5 | 1.41.81.8 | 50 | 1351 | 212 | 608 |

| 50GDL12-15×9 | 8.41214.4 | 2.333.334.0 | 162135108 | 485653 | 2900 | 7.727.878.33 | 11 | 1.41.81.8 | 50 | 1556 | 265 | 683 |

| 50GDL12-15×10 | 8.41214.4 | 2.333.334.0 | 180150120 | 485653 | 2900 | 8.588.759.25 | 11 | 1.41.81.8 | 50 | 1631 | 273 | 758 |

| 50GDL18-15×2 | 12.61821.6 | 3.556 | 363025 | 536262 | 2900 | 2.332.372.37 | 3 | 1.41.81.8 | 50 | 791 | 122 | 158 |

| 50GDL18-15×3 | 2.61821.6 | 3.556 | 544537.5 | 536262 | 2900 | 3.53.563.56 | 4 | 1.41.81.8 | 50 | 926 | 142 | 233 |

| 50GDL18-15×4 | 2.61821.6 | 3.556 | 726050 | 536262 | 2900 | 4.664.754.75 | 5.5 | 1.41.81.8 | 50 | 1051 | 175 | 308 |

| 50GDL18-15×5 | 2.61821.6 | 3.556 | 907562.5 | 536262 | 2900 | 5.835.935.93 | 7.5 | 1.41.81.8 | 50 | 1126 | 189 | 383 |

| 50GDL18-15×6 | 2.61821.6 | 3.556 | 1089075 | 536262 | 2900 | 7.07.127.12 | 7.5 | 1.41.81.8 | 50 | 1201 | 198 | 458 |

| 50GDL18-15×7 | 2.61821.6 | 3.556 | 12610582.5 | 536262 | 2900 | 8.168.308.31 | 11 | 1.41.81.8 | 50 | 1406 | 252 | 533 |

| 50GDL18-15×8 | 2.61821.6 | 3.556 | 144120100 | 536262 | 2900 | 9.329.499.49 | 11 | 1.41.81.8 | 50 | 1481 | 261 | 608 |

| 50GDL18-15×9 | 2.61821.6 | 3.556 | 162135112.5 | 536262 | 2900 | 10.4910.6810.68 | 15 | 1.41.81.8 | 50 | 1556 | 280 | 683 |

| 50GDL18-15×10 | 2.61821.6 | 3.556 | 180150125 | 536262 | 2900 | 11.6611.8711.87 | 15 | 1.41.81.8 | 50 | 1631 | 289 | 758 |

Note: 1. GDLS, GDL-B, and GDLS-B models have the same performance parameters as GDL models except for slight differences in weight and H size. 2. The h1 size is only used for GDLS and GDLS-B models.

Model and Performance Parameter Table3

| 型号 | 流量 | 扬程 | 效率 | 转速 | 功率KW | 汽蚀余量m | 进出口径mm | 高度Hmm | 重量kg | 高度h1mm | ||

| m3/h | L/S | m | % | r/min | 轴功率 | 电机功率 | ||||||

| 65GDL24-12×2 | 16.82428.8 | 4.676.678 | 272422 | 566567 | 2900 | 2.212.415.57 | 3 | 2.933.1 | 65 | 821 | 131 | 160 |

| 65GDL24-12×3 | 16.82428.8 | 4.676.678 | 40.53633 | 566567 | 2900 | 3.313.623.87 | 4 | 2.933.1 | 65 | 936 | 153 | 235 |

| 65GDL24-12×4 | 16.82428.8 | 4.676.678 | 544844 | 566567 | 2900 | 4.414.835.15 | 5.5 | 2.933.1 | 65 | 1061 | 182 | 310 |

| 65GDL24-12×5 | 16.82428.8 | 4.676.678 | 67.56055 | 566567 | 2900 | 5.526.036.44 | 7.5 | 2.933.1 | 65 | 1136 | 198 | 385 |

| 65GDL24-12×6 | 16.82428.8 | 4.676.678 | 817266 | 566567 | 2900 | 6.627.247.73 | 7.5 | 2.933.1 | 65 | 1211 | 214 | 460 |

| 65GDL24-12×7 | 16.82428.8 | 4.676.678 | 94.58477 | 566567 | 2900 | 7.728.459.01 | 11 | 2.933.1 | 65 | 1416 | 263 | 535 |

| 65GDL24-12×8 | 16.82428.8 | 4.676.678 | 1089688 | 566567 | 2900 | 8.839.6510.3 | 11 | 2.933.1 | 65 | 1491 | 273 | 610 |

| 65GDL24-12×9 | 16.82428.8 | 4.676.678 | 121.510899 | 566567 | 2900 | 9.9310.8511.59 | 15 | 2.933.1 | 65 | 1556 | 293 | 685 |

| 65GDL24-12×10 | 16.82428.8 | 4.676.678 | 135120110 | 566567 | 2900 | 11.012.0612.88 | 15 | 2.933.1 | 65 | 1641 | 303 | 760 |

| 80GDL36-12×2 | 25.23643.2 | 71012 | 272421 | 596867 | 2900 | 3.143.463.68 | 4 | 3.544.2 | 80 | 917 | 193 | 182 |

| 80GDL36-12×3 | 25.23643.2 | 71012 | 40.53631.5 | 596867 | 2900 | 4.715.195.53 | 5.5 | 3.544.2 | 80 | 1052 | 227 | 267 |

| 80GDL36-12×4 | 25.23643.2 | 71012 | 544842 | 596867 | 2900 | 6.296.927.37 | 7.5 | 3.544.2 | 80 | 1137 | 244 | 352 |

| 80GDL36-12×5 | 25.23643.2 | 71012 | 67.56052.5 | 596867 | 2900 | 7.868.679.22 | 11 | 3.544.2 | 80 | 1352 | 292 | 437 |

| 80GDL36-12×6 | 25.23643.2 | 71012 | 817263 | 596867 | 2900 | 9.4310.3911.06 | 11 | 3.544.2 | 80 | 1437 | 302 | 522 |

| 80GDL36-12×7 | 25.23643.2 | 71012 | 94.58473.5 | 596867 | 2900 | 11.012.1212.9 | 15 | 3.544.2 | 80 | 1522 | 322 | 607 |

| 80GDL36-12×8 | 25.23643.2 | 71012 | 1089684 | 596867 | 2900 | 12.5813.8514.75 | 15 | 3.544.2 | 80 | 1607 | 332 | 692 |

| 80GDL36-12×9 | 25.23643.2 | 71012 | 121.510894.5 | 596867 | 2900 | 14.1415.5916.5 | 18.5 | 3.544.2 | 80 | 1737 | 365 | 777 |

| 80GDL36-12×10 | 25.23643.2 | 71012 | 135120115 | 596867 | 2900 | 15.7117.3118.4 | 18.5 | 3.544.2 | 80 | 1822 | 375 | 862 |

| 80GDL54-14×2 | 37.85464.8 | 10.51518 | 322825 | 627073.5 | 2900 | 5.325.886.01 | 7.5 | 3.744.2 | 80 | 967 | 218 | 182 |

| 80GDL54-14×3 | 37.85464.8 | 10.51518 | 484237.5 | 627073.5 | 2900 | 7.978.829.01 | 11 | 3.744.2 | 80 | 1182 | 267 | 267 |

| 80GDL54-14×4 | 37.85464.8 | 10.51518 | 645650 | 627073.5 | 2900 | 10.1311.7612.01 | 15 | 3.744.2 | 80 | 1267 | 287 | 352 |

| 80GDL54-14×5 | 37.85464.8 | 10.51518 | 807062.5 | 627073.5 | 2900 | 13.314.715.0 | 18.5 | 3.744.2 | 80 | 1397 | 320 | 437 |

| 80GDL54-14×6 | 37.85464.8 | 10.51518 | 968475 | 627073.5 | 2900 | 15.917.6418.0 | 18.5 | 3.744.2 | 80 | 1482 | 330 | 522 |

| 80GDL54-14×7 | 37.85464.8 | 10.51518 | 1129887.5 | 627073.5 | 2900 | 18.620.5821.0 | 22 | 3.744.2 | 80 | 1592 | 373 | 607 |

| 80GDL54-14×8 | 37.85464.8 | 10.51518 | 128112100 | 627073.5 | 2900 | 21.323.5424 | 30 | 3.744.2 | 80 | 1607 | 400 | 692 |

| 80GDL54-14×9 | 37.85464.8 | 10.51518 | 144126112.5 | 627073.5 | 2900 | 23.926.4927 | 30 | 3.744.2 | 80 | 1757 | 421 | 777 |

| 80GDL54-14×10 | 37.85464.8 | 10.51518 | 160140125 | 627073.5 | 2900 | 26.629.4330 | 37 | 3.744.2 | 80 | 1882 | 432 | 862 |

Note: 1. GDLS, GDL-B, and GDLS-B models have the same performance parameters as GDL models except for slight differences in weight and H size. 2. The h1 size is only used for GDLS and GDLS-B models.

Model and Performance Parameter Table4

| 型号 | 流量 | 扬程 | 效率 | 转速 | 功率KW | 汽蚀余量m | 进出口径mm | 高度Hmm | 重量kg | 高度h1mm | ||

| m3/h | L/S | m | % | r/min | 轴功率 | 电机功率 | ||||||

| 100GDL72-14×2 | 50.47286.4 | 142024 | 322824 | 647273 | 2900 | 6.877.537.74 | 11 | 4.24.54.7 | 100 | 1200 | 276 | 187 |

| 100GDL72-14×3 | 50.47286.4 | 142024 | 484236 | 647273 | 2900 | 10.311.2911.61 | 15 | 4.24.54.7 | 100 | 1335 | 298 | 272 |

| 100GDL72-14×4 | 50.47286.4 | 142024 | 645648 | 647273 | 2900 | 13.715.0515.48 | 18.5 | 4.24.54.7 | 100 | 1460 | 336 | 357 |

| 100GDL72-14×5 | 50.47286.4 | 142024 | 807060 | 647273 | 2900 | 17.1718.8119.35 | 22 | 4.24.54.7 | 100 | 1650 | 381 | 442 |

| 100GDL72-14×6 | 50.47286.4 | 142024 | 968472 | 647273 | 2900 | 20.622.5723.22 | 30 | 4.24.54.7 | 100 | 1740 | 453 | 527 |

| 100GDL72-14×7 | 50.47286.4 | 142024 | 1129884 | 647273 | 2900 | 24.0326.3427.09 | 30 | 4.24.54.7 | 100 | 1825 | 466 | 612 |

| 100GDL72-14×8 | 50.47286.4 | 142024 | 12811296 | 647273 | 2900 | 27.430.130.96 | 37 | 4.24.54.7 | 100 | 1900 | 493 | 697 |

| 100GDL72-14×9 | 50.47286.4 | 142024 | 144126108 | 647273 | 2900 | 30.933.934.83 | 37 | 4.24.54.7 | 100 | 1980 | 582 | 782 |

| 100GDL72-14×10 | 50.47286.4 | 142024 | 160140120 | 647273 | 2900 | 34.337.638.7 | 45 | 4.24.54.7 | 100 | 2070 | 595 | 867 |

| 125GDL100-20×2 | 70100120 | 19.427.733.3 | 464034 | 657373 | 2900 | 13.514.715.2 | 18.5 | 4.24.54.7 | 125 | 1185 | 292 | 204 |

| 125GDL100-20×3 | 70100120 | 19.427.733.3 | 696051 | 657373 | 2900 | 20.222.122.8 | 30 | 4.24.54.7 | 125 | 1315 | 430 | 289 |

| 125GDL100-20×4 | 70100120 | 19.427.733.3 | 928068 | 657373 | 2900 | 2729.530.4 | 37 | 4.24.54.7 | 125 | 1410 | 463 | 394 |

| 125GDL100-20×5 | 70100120 | 19.427.733.3 | 11510085 | 657373 | 2900 | 33.736.838.1 | 45 | 4.24.54.7 | 125 | 1585 | 555 | 489 |

| 125GDL100-20×6 | 70100120 | 19.427.733.3 | 138120102 | 657373 | 2900 | 40.544.245.7 | 55 | 4.24.54.7 | 125 | 1865 | 640 | 584 |

| 125GDL100-20×7 | 70100120 | 19.427.733.3 | 161140119 | 657373 | 2900 | 47.251.553.3 | 75 | 4.24.54.7 | 125 | 1960 | 840 | 479 |

| 125GDL100-20×8 | 70100120 | 19.427.733.3 | 181160136 | 657373 | 2900 | 5458.960.9 | 75 | 4.24.54.7 | 125 | 2055 | 855 | 774 |

| 125GDL100-20×9 | 70100120 | 19.427.733.3 | 207180153 | 657373 | 2900 | 60.766.368.5 | 75 | 4.24.54.7 | 125 | 2225 | 870 | 869 |

| 125GDL100-20×10 | 70100120 | 19.427.733.3 | 230200170 | 657373 | 2900 | 67.573.676.1 | 90 | 4.24.54.7 | 125 | 2370 | 955 | 964 |

| 150GDL160-25×2 | 112160192 | 31.144.453.3 | 565044 | 697877 | 2900 | 24.7727.9529.9 | 37 | 4.44.54.7 | 150 | 1325 | 437 | 205 |

| 150GDL160-25×3 | 112160192 | 31.144.453.3 | 847566 | 697877 | 2900 | 37.1541.9244.84 | 55 | 4.44.54.7 | 150 | 1420 | 596 | 300 |

| 150GDL160-25×4 | 112160192 | 31.144.453.3 | 11210088 | 697877 | 2900 | 49.5455.959.79 | 75 | 4.44.54.7 | 150 | 1705 | 737 | 395 |

| 150GDL160-25×5 | 112160192 | 31.144.453.3 | 140125110 | 697877 | 2900 | 61.9269.8774.74 | 90 | 4.44.54.7 | 150 | 1875 | 856 | 490 |

| 150GDL160-25×6 | 112160192 | 31.144.453.3 | 168150142 | 697877 | 2900 | 74.3183.8596.49 | 110 | 4.44.54.7 | 150 | 1970 | 951 | 585 |

| 150GDL160-25×7 | 112160192 | 31.144.453.3 | 186175144 | 697877 | 2900 | 82.2797.8297.85 | 110 | 4.44.54.7 | 150 | 2115 | 978 | 680 |

Note: 1. GDLS, GDL-B, and GDLS-B models have the same performance parameters as GDL models except for slight differences in weight and H size. 2. The h1 size is only used for GDLS and GDLS-B models.

GDL multi-stage pipeline centrifugal pump

GDL multi-stage pipeline centrifugal pump

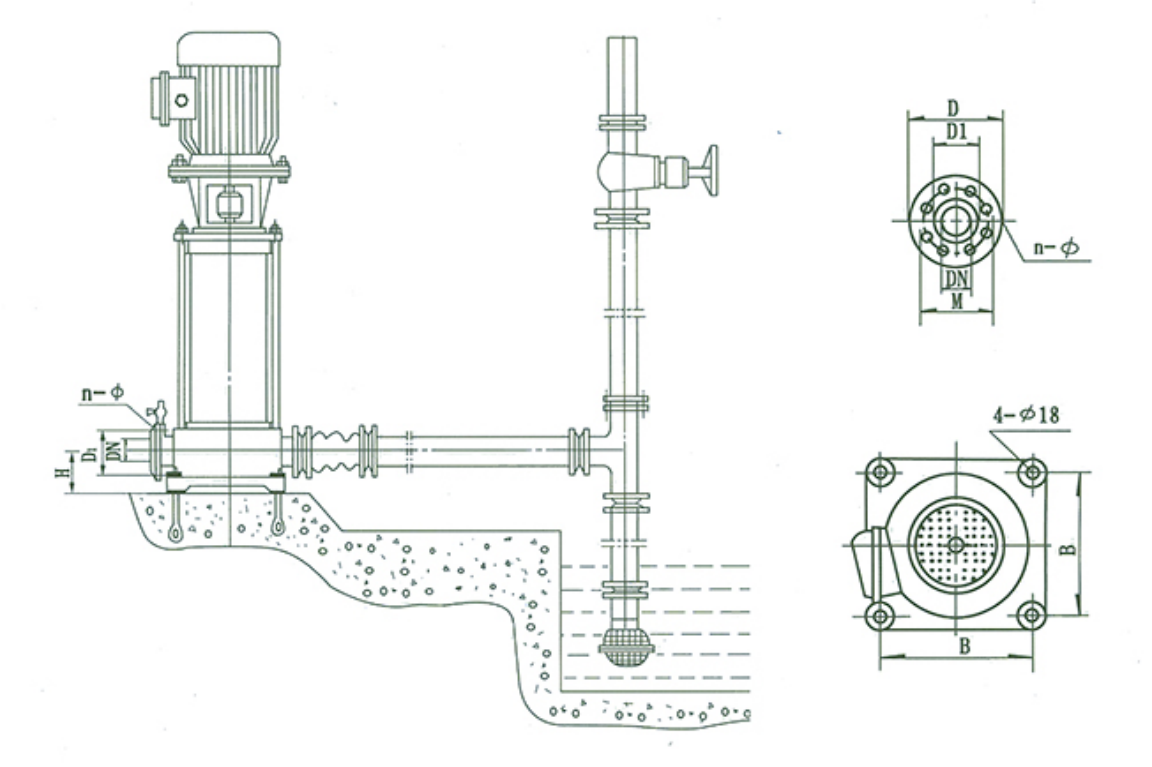

Dimensions and Installation Diagram

Outline installation dimension table

| 型号model | H | L | B×B | 进出口法兰Import and export flanges | |||

| DN | D | D1 | n-ф | ||||

| 25 GDL | 80 | 300 | 2054~ф14 | ф25 | 115 | 85 | 4~ф14 |

| 40 GDL | 85 | 330 | 2054~ф14 | ф40 | 150 | 110 | 4~ф18 |

| 50 GDL | 105 | 365 | 2254~ф18 | ф50 | 165 | 125 | 4~ф18 |

| 65 GDL | 105 | 365 | 2254~ф18 | ф65 | 185 | 145 | 4~ф18 |

| 80 GDL | 130 | 420 | 2904~ф20 | ф80 | 200 | 160 | 8~ф18 |

| 100 GDL | 140 | 520 | 3504~ф20 | ф100 | 220 | 180 | 8~ф18 |

| 125 GDL | 150 | 540 | 3704~ф24 | ф125 | 250 | 210 | 8~ф18 |

| 150 GDL | 175 | 580 | 4104~ф24 | ф150 | 285 | 240 | 8~ф22 |

Installation instructions

1. The weight of the pipeline should not be borne on the pump during installation, otherwise it is easy to damage the water pump;

2. The pump and motor are integral structures that have been calibrated by the manufacturer before leaving the factory, so there is no need to adjust them during installation, making installation very convenient;

3. During installation, the anchor bolts must be tightened, and the pump should be checked at regular intervals to prevent loosening, in order to avoid severe vibrations during pump start-up that may affect its performance.

4. Before installing the water pump, carefully check whether there are any hard objects (such as stones, iron sand, etc.) in the pump flow channel that affect the operation of the water pump to avoid damaging the overcurrent components during the operation of the water pump;

5. For the convenience of maintenance and safety of use, a regulating valve should be installed on the inlet and outlet pipelines of the pump, and a pressure gauge should be installed near the inlet and outlet of the pump. For high lift pumps, to prevent water hammer, a check valve should also be installed in front of the outlet gate valve to cope with sudden power outages and other power loss accidents, so as to ensure that the pump operates under optimal conditions and increase its service life;

6. For working conditions where the liquid level is below the pump inlet and there is no vacuum pump, the installation method according to the installation diagram should be followed. The pump inlet should be filled before starting up and running. At the same time, the inlet pipeline should not have too many bends, and there should be no water or air leakage to avoid affecting the suction performance of the water pump.

7. To prevent impurities from entering the pump and blocking the flow path, a filter should be installed in front of the pump inlet to improve performance;

8. Before installing the pipeline, rotate the rotor components of the water pump without any friction sound or jamming phenomenon. Otherwise, the pump should be disassembled to check the cause.

GDL multi-stage pipeline centrifugal pump