Your location:

Product classification of Meiyan One Pump Valve

- ShangHai Meiyan Yi Pump & Valve Co.,LTD.

- Sales hotline:

+86 21 5640 2009 - Pump customer service:

+86 138 1691 3072 - Valve customer service:

+86 1381 6913 072 - E-mail:

my1pv@1bengfa.com

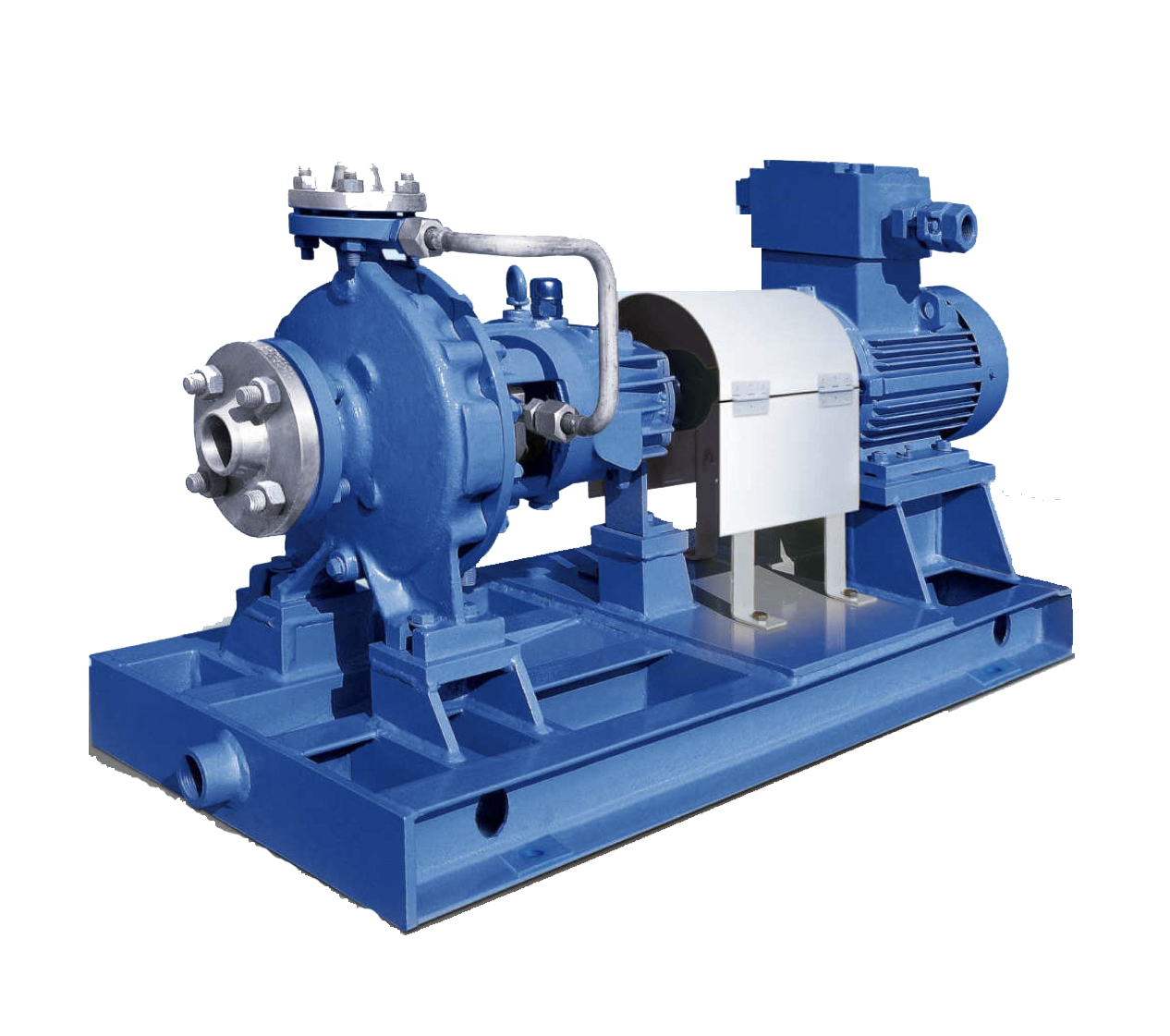

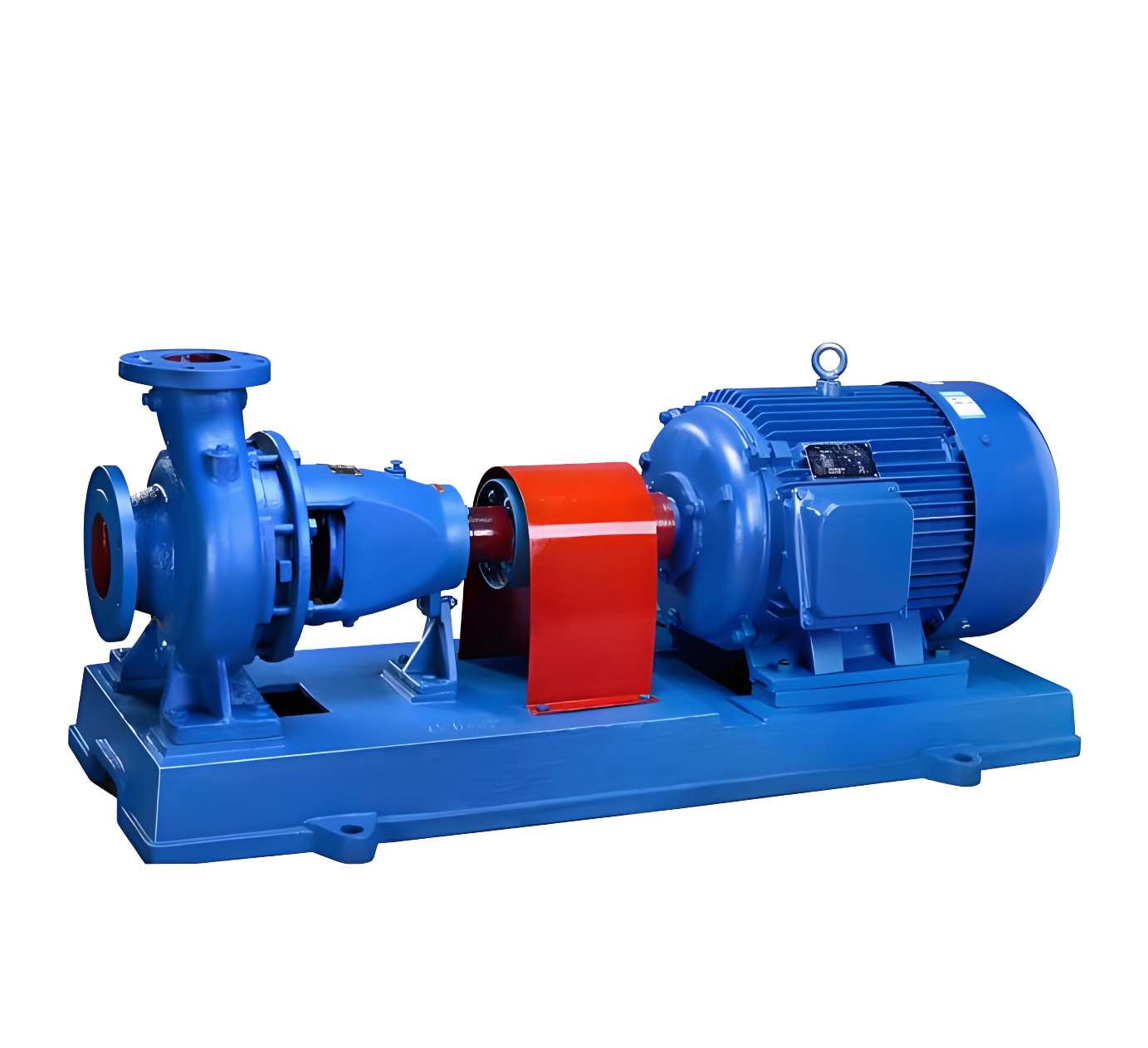

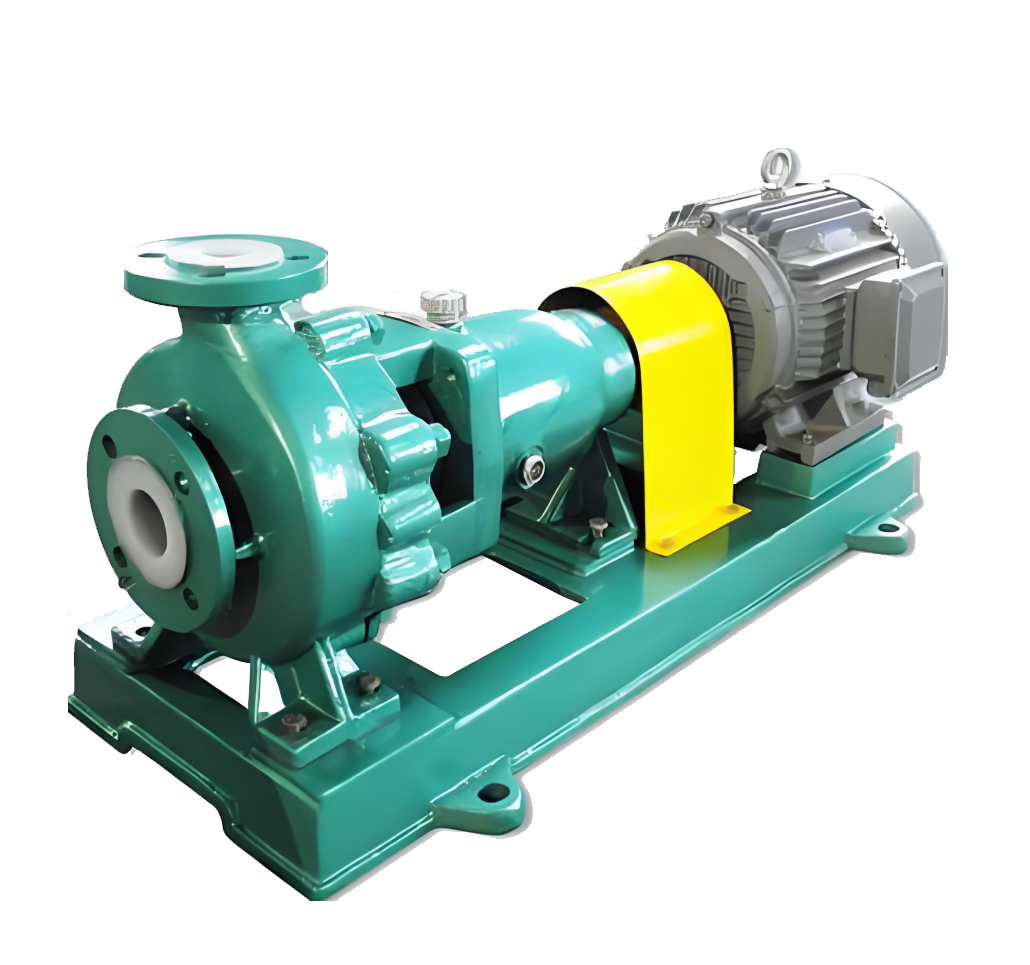

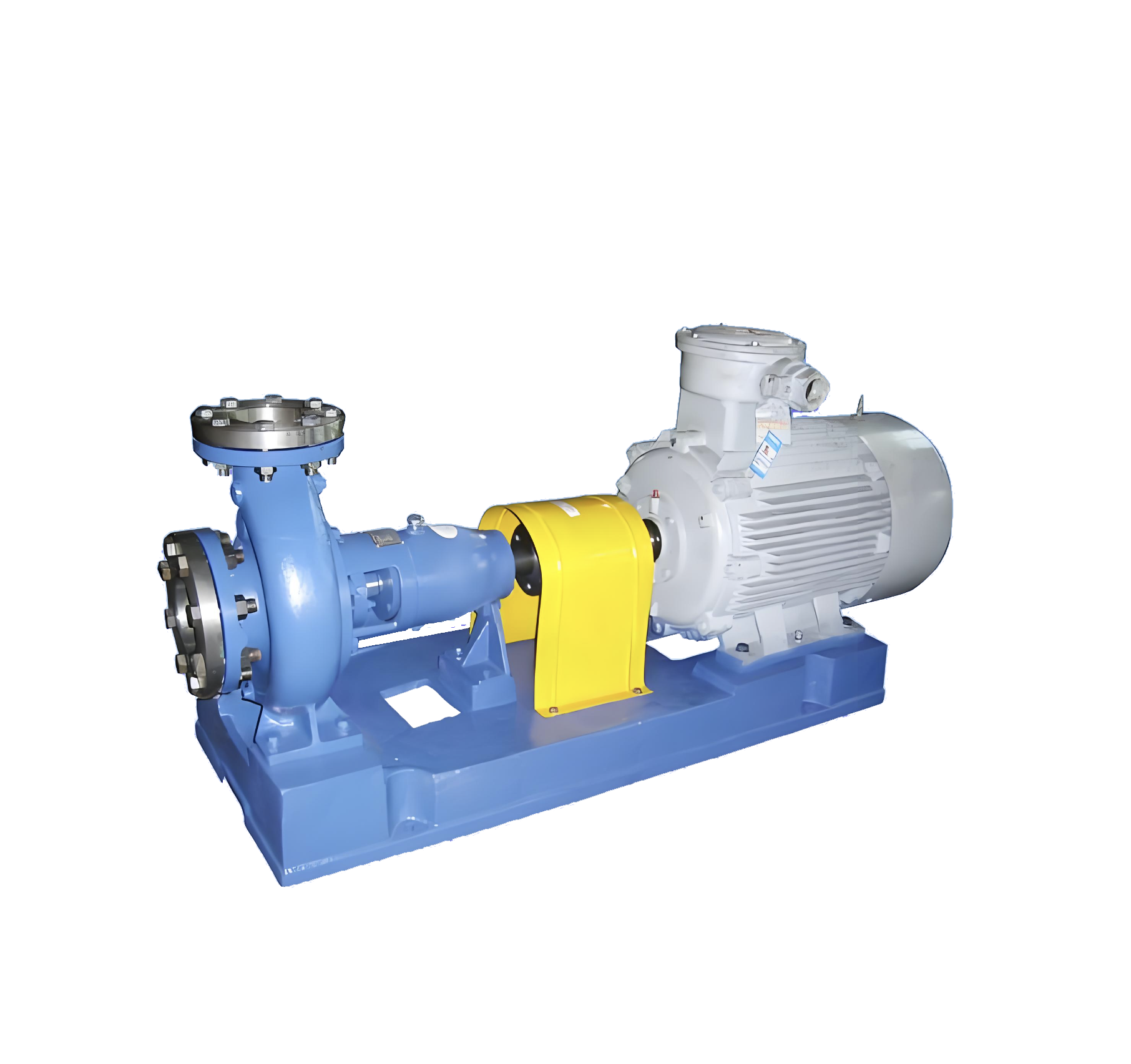

SJB acid resistant and wear-resistant pump

- Brand:YI PUMP VALVE

- Type:SJB

- PN/H:5~80米

- Heat:-20℃~120℃

- Connection Type:flange

- Product Name:SJB acid resistant and wear-resistant pump

- Diameter:3.2~400T/h

- Material:alloy steel

- Driven Mode:electric

- Applicable Scope:Suitable for the transportation of iron oxide scale liquid, mud liquid, coal slag liquid, lime slag liquid, and titanium dioxide powder liquid.

- Product Overview

- Performance Data

- Size Weight

SJB acid resistant and wear-resistant pump

Structural Characteristics

SJB series acid - resistant and wearable pump is our introduction, assimilation, Germany advanced technology, combined with the practical needs of domestic product development from a sin-gle-stage single-suction centrifugal pump. Pump parts are all over - current and high mechanical strength, wear resistance, good corrosion performance of metallic materials, high temperature, high pressure molding time. shell com-pression, impact of high - quality A3 steel is made by investment casting. all used mechanical sealwear and corrosion performance of the best crafted pressureless sintered silicon carbide mechanicalseal system technology is unique, long seal life The pump is widely used in temperature lower than 120 ℃, with hard (soft) mass of solidparticles of acid, alkali, salt, including hydrofluoric acid, strong oxidizing agents, organic solventssuch as the transmission medium (solid content below 40%). especially suitable for liquid iron oxideskin, liquid mud, coal liquid, liquid rock ash, titanium dioxide, liquid delivery, also applies to themetallurgical industry of pickling lines, acid regeneration, and in stations and degreasing, as well asthe use of molybdenum ore industry, completely replace the imported products.

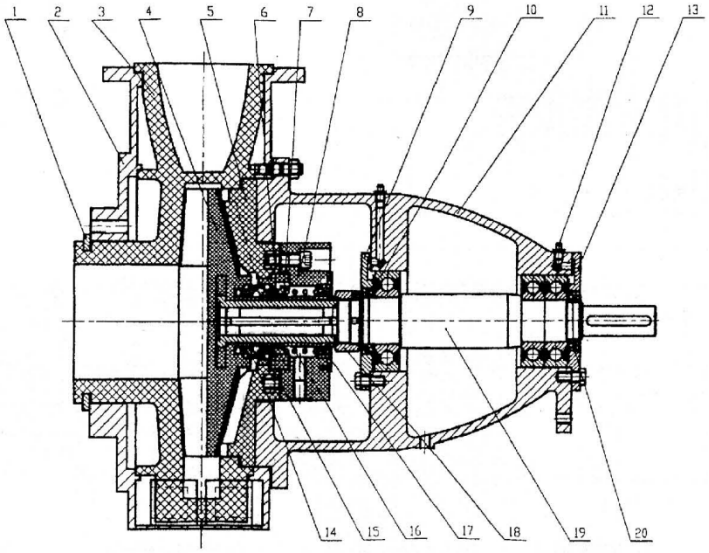

SJB acid resistant and wear-resistant pump product diagram

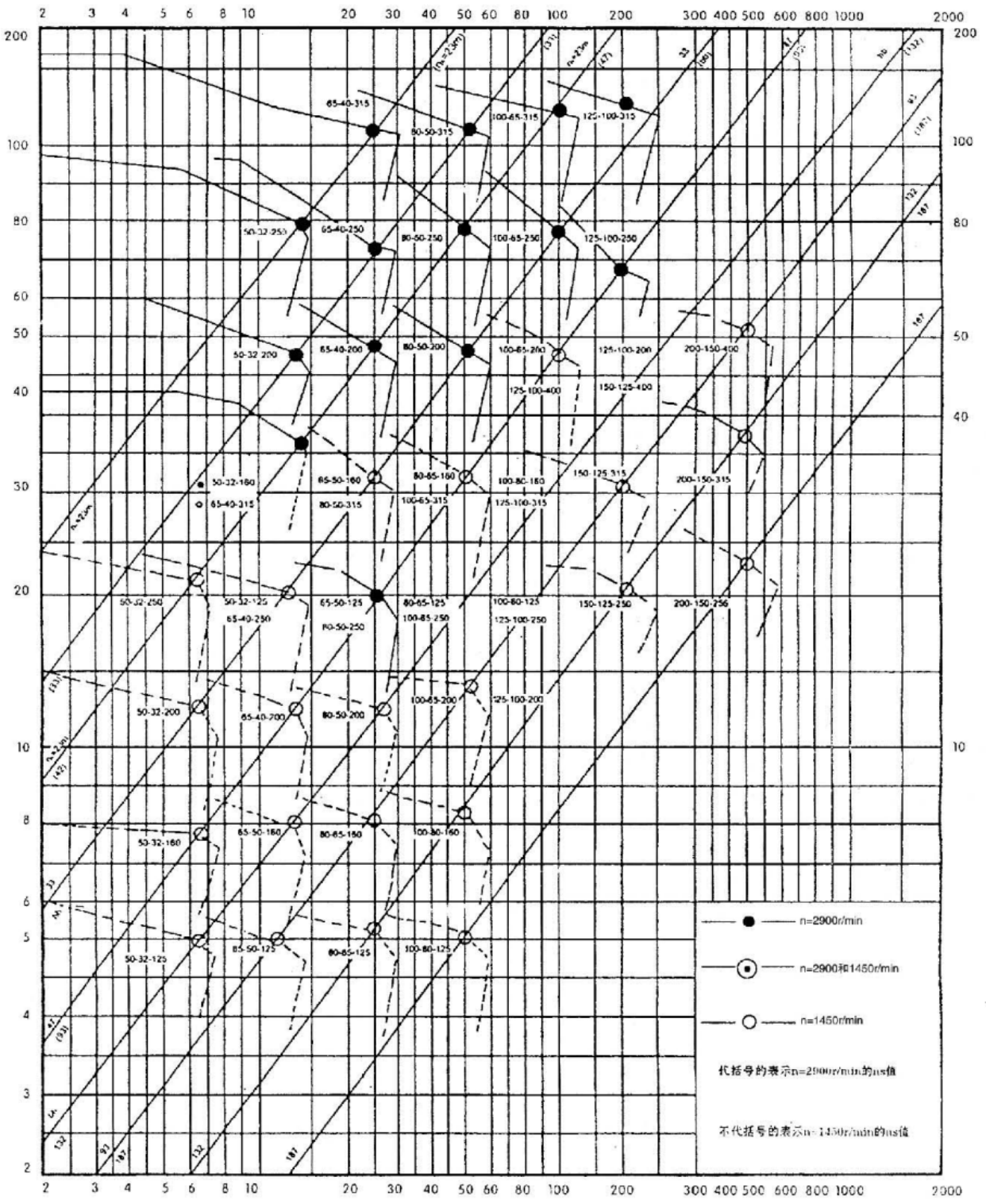

Structural curve for SJB series acid-resistant and wearable pump

Component Name:1、pump body ring 2、shell of pump 3,pump body 4,impeller 5,pump cover 6,static ring base 7.spring base 8.seal cover 9,front cover of bear 10,bear 11,support 12,butter nozzle 13, behind cover of bear 14.ring for mechanical seal 15,static ring for mechanical seal 16,spring 17,seal 18stop nut 19,shaft 20,skeleton oil seal

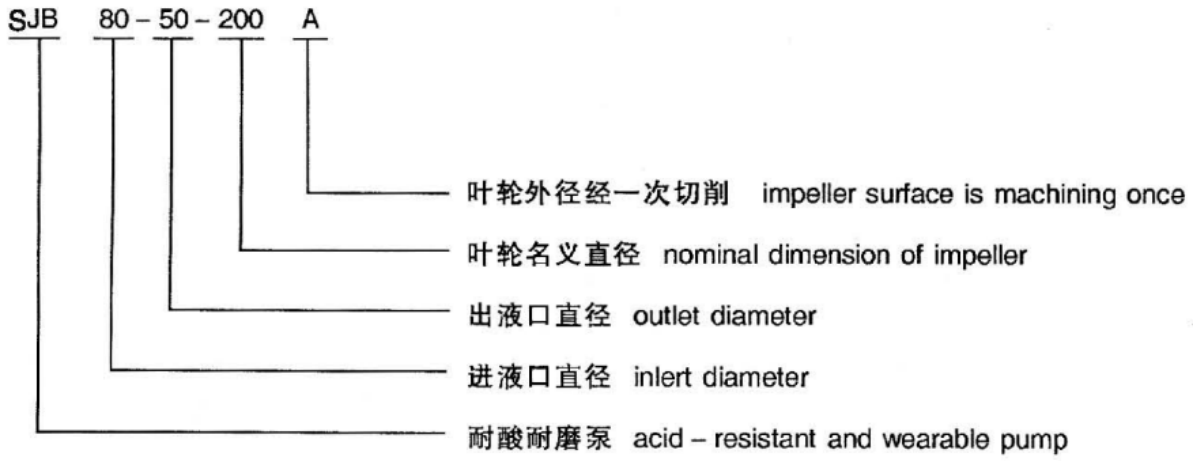

Model introduction

Property curve for Sjb series aciS-resistant anS wearable pump

Performance parameter table of SJB series acid resistant and wear-resistant centrifugal pump

| 泵型号pump model | 流量flow | 扬程 | 转速running speed(r/min) | 功率power(KW) | 效率efficiency(% | 必需汽蚀余量NPSHr(m) | ||

| m³/h | I/s | 轴功率bear power | 配用功率nominal power | |||||

| SJB40-32-125 | 6.3 | 1.74 | 20 | 2900 | 0.66 | 3 | 52 | 5 |

| SJB40-32-125 | 3.2 | 0.88 | 5 | 1450 | 0.09 | 0.75 | 46 | 5 |

| SJB40-32-160 | 6.3 | 74 | 32 | 2900 | 1.17 | 4 | 47 | 5 |

| SJB40-32-160 | 3.2 | 0.88 | 8 | 1450 | 0.17 | 1.1 | 42 | 5 |

| SJB40-32-200 | 6.3 | 1.74 | 50 | 2900 | 2.26 | 7.5 | 38 | 5 |

| SJB40-32-200 | 3.2 | 0.88 | 12.5 | 1450 | 0.29 | .5 | 38 | 5 |

| SJB40-32-250 | 6.3 | 1.74 | 80 | 2900 | 4.28 | 15 | 32 | 5 |

| SJB40-32-250 | 3.2 | 0.88 | 20 | 1450 | 0.49 | 2.2 | 35 | 5 |

| SJB50-32-125 | 12.5 | 3.47 | 20 | 2900 | 1.33 | 4 | 36 | 3.8 |

| SJB50-32-125 | 6.3 | 1.75 | 5 | 1450 | 0.19 | 0.75 | 30 | 3.5 |

| SJB50-32-160 | 12.5 | 3.47 | 32 | 2900 | 2.37 | 5.5 | 31 | 3.8 |

| SJB50-32-160 | 6.3 | 1.75 | 8 | 1450 | 0.34 | 1.1 | 25 | 3.5 |

| SJB50-32-200 | 2.5 | 3.47 | 50 | 2900 | 4.38 | 11 | 24 | 3.8 |

| SJB50-32-200 | 6.3 | 1.75 | 12.5 | 1450 | 0.65 | 1.5 | 18 | 3.5 |

| SJB50-32-250 | 12.5 | 3.47 | 80 | 2900 | 8.25 | 18.5 | 23 | 3.8 |

| SJB50-32-250 | 6.3 | 1.75 | 20 | 1450 | 1.27 | 2.2 | 20 | 3.5 |

| SJB65-50-125 | 25 | 6.94 | 20 | 2900 | 2.2 | 5.5 | 46 | 3.8 |

| SJB65-50-12F | 12.5 | 3.47 | 5 | 1450 | 0.31 | 0.75 | 40 | 3.5 |

| SJB65-50-160 | 25 | 6.94 | 32 | 2900 | 3.82 | 7.5 | 42 | 3.8 |

| SJB65-50-160 | 12.5 | 3.47 | 8 | 1450 | 0.53 | 1.5 | 36 | 3.5 |

| SJB65-40-200 | 25 | 6.94 | 50 | 2900 | 6.55 | 15 | 37 | 3.8 |

| SJB65-40-200 | 12.5 | 3.47 | 12.5 | 1450 | 0.93 | 2.2 | 31 | 3.5 |

| SJB65-40-250 | 25 | 6.94 | 80 | 2900 | 11.84 | 22 | 31 | 3.8 |

| SJB65-40-250 | 12.5 | 3.47 | 20 | 1450 | 1.75 | 4 | 27 | 3.5 |

| SJB65-40-315 | 25 | 6.94 | 125 | 2900 | 21.8 | 37 | 27 | 3.8 |

| SJB65-40-315 | 12.5 | 3.47 | 32 | 1450 | 3.3 | 7.5 | 25 | 3.5 |

| SJB80-65-125 | 50 | 12.88 | 20 | 2900 | 3.95 | 7.5 | 57 | 4 |

| SJB80-65-125 | 25 | 6.94 | 5 | 1450 | 0.53 | 1.5 | 54 | 3.8 |

| SJB80-65-160 | 50 | 13.88 | 32 | 2900 | 6.5 | 11 | 51 | 4 |

| SJB80-65-160 | 25 | 6.94 | 8 | 1450 | 0.88 | 2.2 | 46 | 3.8 |

| SJB80-50-200 | 50 | 13.88 | 50 | 2900 | 10.8 | 18.5 | 47 | 4 |

| SJB80-50-200 | 25 | 6.94 | 12.5 | 1450 | 1.49 | 3 | 42 | 3.8 |

| SJB80-50-250 | 50 | 13.88 | 80 | 2900 | 19.11 | 37 | 42 | 4 |

| SJB80-50-250 | 25 | 6.94 | 20 | 1450 | 2.57 | 5.5 | 38 | 3.8 |

| SJB80-50-315 | 25 | 6.94 | 32 | 1450 | 5.06 | 11 | 30 | 3.8 |

| SJB80-50-400 | 25 | 6.94 | 50 | 1450 | 9.64 | 15 | 24 | 3.8 |

| SJB100-80-125 | 100 | 27.77 | 20 | 2900 | 7.074 | 15 | 61 | 4.5 |

| SJB100-80-125 | 50 | 13.88 | 5 | 1450 | 0.92 | 2.2 | 57 | 4 |

| SJB100-80-160 | 100 | 27.77 | 32 | 2900 | 11.9 | 18.5 | 57 | 4.5 |

| SJB100-80-16C | 50 | 13.88 | 8 | 1450 | 1.58 | 4 | 53 | 4 |

| SJB100-65-200 | 100 | 27.77 | 50 | 2900 | 18.9 | 37 | 56 | 4.5 |

| SJB100-65-200 | 50 | 13.88 | 12.5 | 1450 | 2.5 | 5.5 | 52 | 4 |

| SJB100-65-250 | 100 | 27.77 | 80 | 2900 | 32 | 45 | 54 | 4.5 |

| SJB100-65-250 | 50 | 13.88 | 20 | 1450 | 4.3 | 7.5 | 49 | 4 |

| SJB100-65-315 | 50 | 13.88 | 32 | 1450 | 7.5 | 15 | 43 | 4 |

| SJB125-100-200 | 200 | 55.55 | 50 | 2900 | 35.4 | 55 | 61 | 4.8 |

| SJB125-100-200 | 100 | 27.77 | 12.5 | 1450 | 4.66 | 11 | 57 | 4.5 |

| SJB125-100-250 | 200 | 55.55 | 80 | 2900 | 58.1 | 90 | 59 | 4.8 |

| SJB125-100-257 | 100 | 27.77 | 20 | 1450 | 7.56 | 15 | 56 | 4.5 |

| STR125-100-315 | 100 | 27.77 | 32 | 1450 | 12.82 | 22 | 52 | 4.5 |

| SJB125-100-400 | 100 | 27.77 | 50 | 1450 | 22.69 | 37 | 49 | 4.5 |

| SJB150-125-250 | 200 | 55.55 | 20 | 1450 | 14.1 | 22 | 61 | 4.8 |

| SJB150-125-315 | 200 | 55.55 | 32 | 1450 | 23.2 | 37 | 59 | 4.8 |

| SJB150-125-400 | 200 | 55.55 | 50 | 1450 | 38.9 | 75 | 57 | 4.8 |

| SJB200-150-250 | 400 | 111.1 | 20 | 1450 | 26.9 | 45 | 65 | 5 |

| SJB200-150-315 | 400 | 111.1 | 32 | 1450 | 44.4 | 75 | 63 | 5 |

| SJB200-150-400 | 400 | 111.1 | 50 | 1450 | 69.8 | 110 | 62 | 5 |

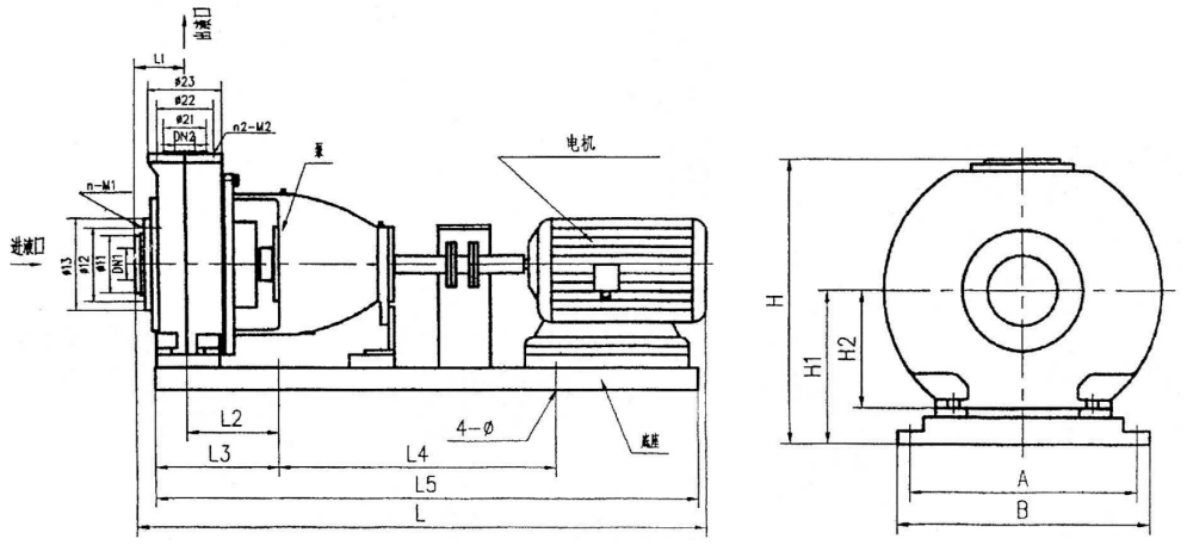

SJB series acid resistant and wear-resistant centrifugal pump external installation dimension diagram

Dimension table of SJB series acid-resistant and wearable pump:

| 泵型号Pump model | 配用电机型号 model of motor | L1 | L2 | L3 | L4 | L5 | L | H1 | H2 | H | A | B | 4-d | 进液口法兰fluid inlet flange | 出液口法兰fluid outlet flange | ||||||||

| DN1 | φ11 | φ12 | φ13 | n-M1 | DN2 | 021 | φ22 | φ23 | n2-M2 | ||||||||||||||

| SJB40-32-125 | 3KW-2 | 80 | 15 | 100 | 600 | 850 | 910 | 212 | 132 | 372 | 350 | 390 | 4-①19 | 40 | 88 | 110 | 15 | 4-M16 | 32 | 76 | 100 | 140 | 4-M16 |

| 0.75KW-4 | 80 | 15 | 100 | 600 | 850 | 900 | 212 | 132 | 372 | 350 | 390 | 4-φ19 | |||||||||||

| SJB40-32-160 | 4KW-2 | 80 | 15 | 100 | 600 | 850 | 987 | 212 | 132 | 372 | 350 | 390 | 4-φ19 | ||||||||||

| 1.1KW-4 | 80 | 15 | 100 | 600 | 850 | 900 | 212 | 132 | 372 | 350 | 390 | 4-①19 | |||||||||||

| SJB40-32-200 | 7.5KW-2 | 80 | 75 | 160 | 600 | 870 | 1300 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | ||||||||||

| 1.5KW-4 | 80 | 15 | 100 | 600 | 850 | 1000 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | |||||||||||

| SJB40-32-250 | 15KW-2 | 100 | 80 | 160 | 840 | 1170 | 1255 | 280 | 180 | 505 | 490 | 540 | 4-φ19 | ||||||||||

| 2.2KW-4 | 100 | 120 | 220 | 640 | 1000 | 1080 | 270 | 180 | 495 | 460 | 520 | 4-φ19 | |||||||||||

| SJB50-32-125 | 4KW-2 | 80 | 15 | 100 | 600 | 850 | 893 | 212 | 132 | 372 | 350 | 390 | 4-019 | 50 | 99 | 125 | 165 | 4-M16 | 32 | 76 | 100 | 140 | 4-M16 |

| 0.75KW-4 | 80 | 15 | 100 | 600 | 850 | 860 | 212 | 132 | 372 | 350 | 390 | 4-019 | |||||||||||

| SJB50-32-160 | 5.5KW-2 | 80 | 75 | 160 | 600 | 870 | 970 | 212 | 132 | 372 | 350 | 390 | 4-φ19 | ||||||||||

| 1.1KW-4 | 80 | 15 | 100 | 600 | 850 | B70 | 212 | 132 | 372 | 350 | 390 | 4-φ19 | |||||||||||

| SUB50-32-200 | 11KW-2 | 80 | 55 | 140 | 740 | 1000 | 1100 | 240 | 160 | 420 | 440 | 490 | 4-019 | ||||||||||

| 2.2KW-4 | 80 | 15 | 100 | 600 | 850 | 930 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | |||||||||||

| SJB50-32-250 | 18.5KW-2 | 100 | 80 | 160 | 840 | 1170 | 1255 | 280 | 180 | 505 | 490 | 540 | 4-019 | ||||||||||

| 3KW-4 | 100 | 120 | 220 | 620 | 1000 | 1010 | 270 | 180 | 495 | 460 | 520 | 4-019 | |||||||||||

| SJB65-50-125 | 5.5KW-2 | 80 | 75 | 160 | 600 | 870 | 970 | 192 | 112 | 332 | 350 | 390 | 4-φ19 | 65 | 118 | 145 | 185 | 4-M16 | 50 | 99 | 125 | 165 | 4-M16 |

| 0.75KW-4 | 80 | 15 | 100 | 600 | 850 | 910 | 192 | 112 | 332 | 350 | 390 | 4-①19 | |||||||||||

| SJB65-50-160 | 7.5KW-2 | 80 | 75 | 160 | 600 | 870 | 987 | 212 | 132 | 372 | 350 | 390 | 4-φ19 | ||||||||||

| 1.5KW-4 | 80 | 15 | 100 | 600 | 850 | 900 | 212 | 132 | 372 | 350 | 390 | 4-019 | |||||||||||

| SJB65-40-200 | 15KW-2 | 100 | 80 | 160 | 840 | 1170 | 1280 | 280 | 180 | 505 | 490 | 540 | 4-φ19 | 40 | 84 | 110 | 150 | 4-M16 | |||||

| 2.2KW-4 | 100 | 15 | 100 | 600 | 850 | 1000 | 270 | 180 | 495 | 460 | 520 | 4-019 | |||||||||||

| SJB65-40-250 | 22KW-2 | 100 | 80 | 160 | 840 | 1170 | 1255 | 280 | 180 | 505 | 490 | 540 | 4-①19 | ||||||||||

| 4KW-4 | 100 | 95 | 195 | 640 | 1000 1080 | 270 | 180 | 495 | 460 | 520 | 4-φ19 | ||||||||||||

| SJB65-40-315 | 37KW-2 | 125 | 45 | 160 | 940 | 1240 1430 | 300 | 200 | 550 | 550 | 610 | 4-φ24 | |||||||||||

| 7.5KW-4 | 125 | 95 | 195 | 640 | 1000 1170 | 290 | 200 | 540 | 460 | 520 | 4-φ19 | ||||||||||||

Dimension table 2 of SJB series acid-resistant and wearable pump:

| 泵型号Pump model | 配用电机型号 mode of motor | L1 | L2 | L3 | L4 | L5 | L | H1 | H2 | H | A | B | 4-d | 进液口法兰fluid inlet flange | 出液口法兰fluid outlet flange | ||||||||

| DN1 | φ11 | φ12 | φ13 | n-M1 | DN2 | φ21 | φ22 | φ23 n2-M2 | |||||||||||||||

| SJB80-65-125 | 7.5KW-2 | 100 | 75 | 160 | 600 | 870 | 987 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | 80 | 132 | 160 | 200 | 8-M16 | 65 | 118 | 145 | 185 | 4-M16 |

| 1.5KW-4 | 100 | 15 | 100 | 600 | 850 | 900 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | |||||||||||

| SJB80-65-160 | 11KW-2 | 100 | 55 | 140 | 740 | 1000 | 1145 | 240 | 160 | 420 | 440 | 490 | 4-019 | ||||||||||

| 2.2KW-4 | 100 | 15 | 100 | 600 | 850 | 920 | 240 | 160 | 420 | 350 | 390 | 4-φ19 | |||||||||||

| SJB80-50-200 | 18.5KW-2 | 100 | 55 | 140 | 740 | 1000 | 1200 | 240 | 160 | 440 | 440 | 490 | 4-φ19 | 50 | 99 | 125 | 165 | 4-M16 | |||||

| 3KW-4 | 100 | 15 | 100 | 600 | 850 | 950 | 240 | 160 | 440 | 350 | 390 | 4-φ19 | |||||||||||

| SJB80-50-250 | 37KW-2 | 125 | 45 | 160 | 940 | 1240 | 1580 | 280 | 180 | 505 | 550 | 610 | 4-①24 | ||||||||||

| 5.5KW-2 | 125 | 95 | 195 | 640 | 1000 | 1150 | 265 | 180 | 490 | 460 | 520 | 4-φ24 | |||||||||||

| SJB80-50-315 | 11KW-4 | 125 | 90 | 210 | 780 | 1220 | 1350 | 315 | 225 | 595 | 540 | 610 | 4-024 | ||||||||||

| SJB80-50-400 | 15KW-4 | 125 | 142 | 250 | 740 | 1300 | 1400 | 400 | 280 | 715 | 600 | 660 | 4-①24 | ||||||||||

| SJB100-80-125 | 15KW-2 | 100 | 80 | 160 | 840 | 1170 | 1373 | 260 | 160 | 460 | 490 | 550 | 4-019 | 100 | 156 | 180 | 220 | 8-M16 | 80 | 132 | 160 | 200 | 8-M16 |

| 2.2KW-4 | 100 | 95 | 195 | 640 | 1050 | 1180 | 250 | 160 | 450 | 460 | 520 | 4-φ19 | |||||||||||

| SJB100-80-160 | 18.5KW-2 | 100 | 80 | 160 | 840 | 1170 | 1373 | 260 | 160 | 460 | 490 | 550 | 4-φ24 | ||||||||||

| 4KW-4 | 100 | 95 | 195 | 640 | 1050 | 1180 | 250 | 160 | 450 | 460 | 520 | 4-φ24 | |||||||||||

| SJB100-65-200 | 37KW-2 | 125 | 45 | 160 | 940 | 1240 | 1470 | 280 | 200 | 505 | 550 | 610 | 4-024 | 65 | 118 | 145 | 185 | 4-M16 | |||||

| 5.5KW-4 | 125 | 100 | 195 | 640 | 1050 | 1180 | 290 | 200 | 540 | 470 | 525 | 4-024 | |||||||||||

| SJB100-65-250 | 45KW-2 | 125 | 90 | 210 | 860 | 1350 | 1500 | 370 | 200 | 620 | 550 | 610 | 4-φ24 | ||||||||||

| 7.5KW-4 | 125 | 95 | 195 | 640 | 1050 | 1180 | 290 | 200 | 540 | 460 | 520 | 4-O24 | |||||||||||

| SJB100-65-315 | 15KW-4 | 125 | 90 | 210 | 780 | 1220 | 1350 | 315 | 225 | 595 | 540 | 610 | 4-φ24 | ||||||||||

| SJB125-100-200 | 55KW-2 | 140 | 90 | 210 | 860 | 1240 | 1605 | 400 | 225 | 680 | 550 | 610 | 4-024 | 125 | 184 | 210 | 250 | 8-M16 | 100 | 156 | 180 | 220 | 8-M16 |

| 11KW-4 | 140 | 110 | 210 | 780 | 1220 | 1650 | 315 | 225 | 600 | 540 | 600 | 4-φ24 | |||||||||||

| SJB125-100-250 | 90KW-2 | 140 | 110 | 210 | 1000 | 1450 | 1800 | 400 | 225 | 680 | 630 | 645 | 4-O24 | ||||||||||

| 15KW-4 | 140 | 110 | 210 | 780 | 1220 | 1650 | 315 | 225 | 600 | 540 | 600 | 4-φ24 | |||||||||||

| SJB125-100-315 | 22KW-4 | 140 | 120 | 250 | 860 | 1350 | 1600 | 380 | 250 | 695 | 600 | 660 | 4-φ24 | ||||||||||

| SJB125-100-400 | 37KW-4 | 140 | 142 | 275 | 860 | 1350 | 1650 | 410 | 280 | 765 | 600 | 660 | 4-φ24 | ||||||||||

| SJB150-125-250 | 22KW-4 | 140 | 120 | 250 | 860 | 1350 | 1600 | 340 | 250 | 700 | 540 | 600 | 4-φ24 | 150 | 211 | 240 | 285 | 8-M20 | 125 | 184 | 210 | 250 | 8-M16 |

| SJB150-125-315 | 37KW-4 | 140 | 142 | 275 | 860 | 1350 | 1700 | 400 | 280 | 755 | 600 | 660 | 4-φ24 | ||||||||||

| SUB150-125-400 | 75KW-4 | 140 | 100 | 200 | 1100 | 1590 | 1950 | 435 | 315 | 835 | 600 | 660 | 4-①24 | ||||||||||

| SJB200-150-250 | 45KW-4 | 160 | 142 | 275 | 860 | 1350 | 1750 | 410 | 280 | 785 | 600 | 660 | 4-φ24 | 200 | 266 | 295 | 340 | 12-M20 | 150 | 211 | 240 | 285 | 8-M20 |

| SJB200-150-315 | 75KW-4 | 160 | 280 | 400 | 940 | 1800 | 2500 | 475 | 315 | 875 | 645 | 720 | 4-φ24 | ||||||||||

| SJB200-150-400 | 110KW-4 | 160 | 195 | 310 | 1060 | 1800 | 2500 | 430 | 315 | 880 | 750 | 850 | 4-φ24 | ||||||||||

Assembly for SJB series acid-resistant and wearable pump

1、Pump installation is reasonable or not, having a very important influence in operation and

service life of the pump, it must be calibrated carefully before installation.

2、You should ensure that the pump at work, not exceeding the allowable range of npsh.

3、 inlet the fluid pipe and outlet fluid pipe of pump should have support, instead of using thepump as support .

4、The install place should easy to check and maintain .

5.assembly order :

a、Check before installation for any loading, unloading and transport process and fixing thedamage caused by loose connections .

b、lnstallation of pumps based application level plane leveling instrument, to be based on cementsolidification , wil pump placed in basis , check with spirit level the level of the pump and motor shaftsuch as a standard not applied horn tone is, until the level up. then filling the base with cemengrouting holes and bolt holes .

c、 After cement dries, check the base and bolt hole is loose, tighten the anchor bolts after theright to re - check the level of degree; check the pump shaft and motor shaft concentricity measurement coupling cylindrical, the upper and lower , left and right of the differences should not ex.ceed 0. 1mm, in two weeks, the largest and the smallest gap difference shall not exceed 0.3mm.

d、when the location of pump above the surface of liquid, you should fitted into the bottom valveat the bottom of inlet liquid pipe and fluid control irigation fluid set screw or valve for pre -- irrigationpumps. installation of pumps is lower than the surface should be piping in the pump into the fluidcontrol valve and filtration devices to upload, so as to avoid large debris suction pump.