Your location:

Product classification of Meiyan One Pump Valve

- ShangHai Meiyan Yi Pump & Valve Co.,LTD.

- Sales hotline:

+86 21 5640 2009 - Pump customer service:

+86 138 1691 3072 - Valve customer service:

+86 1381 6913 072 - E-mail:

my1pv@1bengfa.com

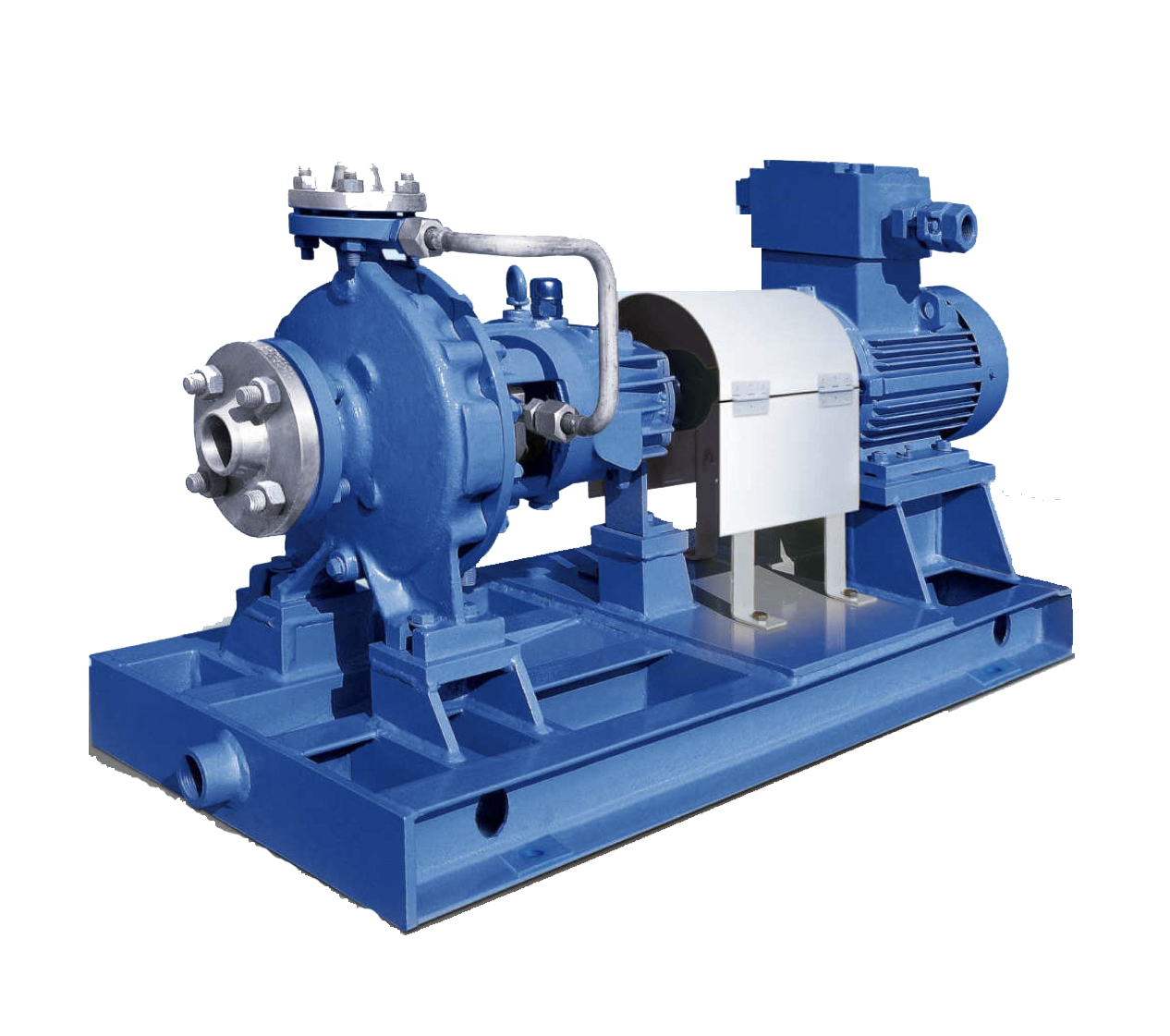

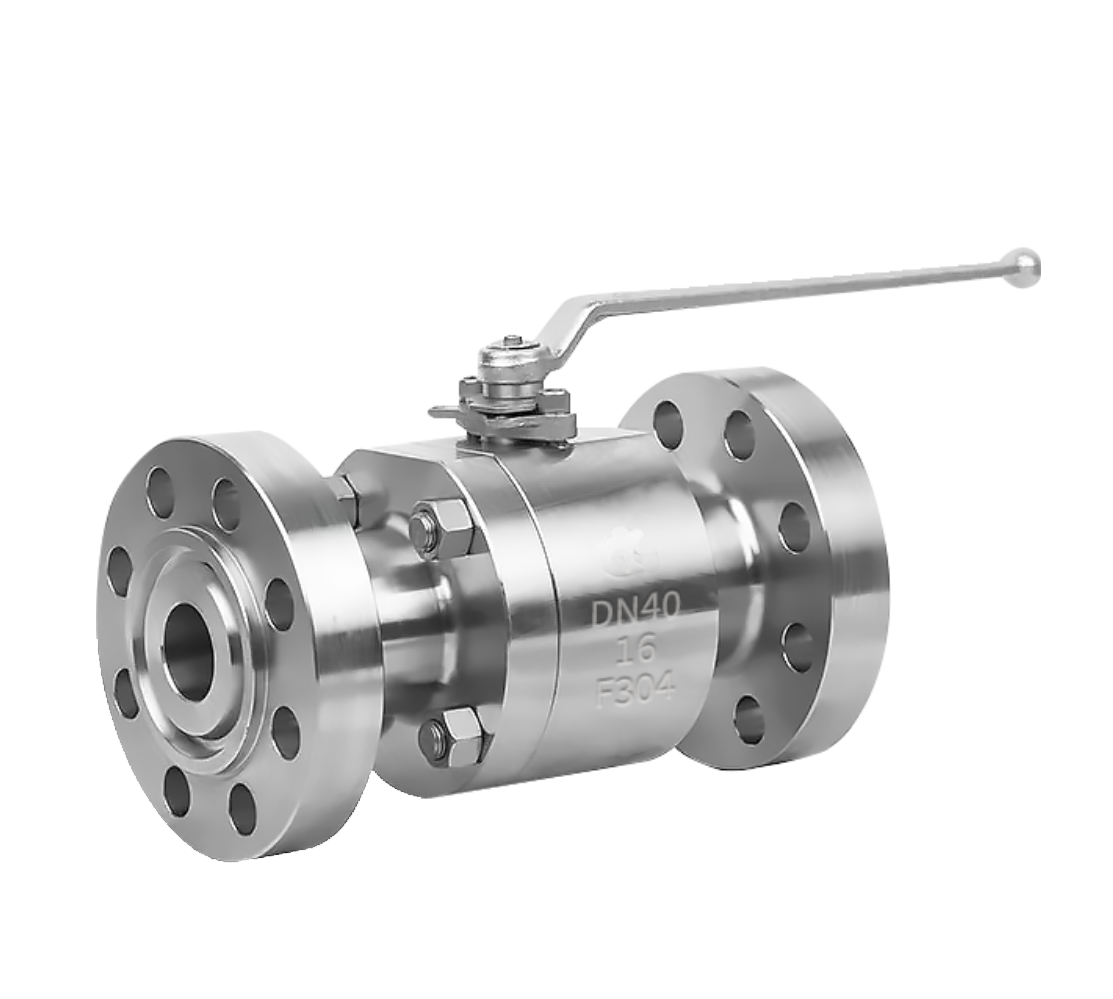

IS clear water /IR hot water centrifugal pump

- Brand:YI PUMP VALVE

- Type:IS、IR、IH

- PN/H:4~125m

- Heat:0℃~120℃

- Connection Type:flange

- Product Name:IS clear water /IR hot water centrifugal pump

- Diameter:0.93~460T/h

- Material:Cast iron, stainless steel SS304、SS304L、SS316、SS316L

- Driven Mode:electric

- Applicable Scope:Suitable for clear water and liquids with physical and chemical properties similar to water without solid particles.

- Product Overview

- Performance Data

- Size Weight

IS clear water centrifugal pump, IR hot water centrifugal pump

Purpose and characteristics

IS and IR type pumps are horizontal, single-stage, single suction, cantilever centrifugal pumps (referred to as IS single-stage horizontal clear water centrifugal pump, IR single-stage horizontal hot water centrifugal pump, IH chemical centrifugal pump), used for sucking and delivering clear water and liquids with physical and chemical properties similar to water without solid particles. The IS and IR pumps produced by Shanghai Meiyan Yi Pump Valve are widely used in industrial, agricultural, urban, drainage, fire water supply and other occasions.

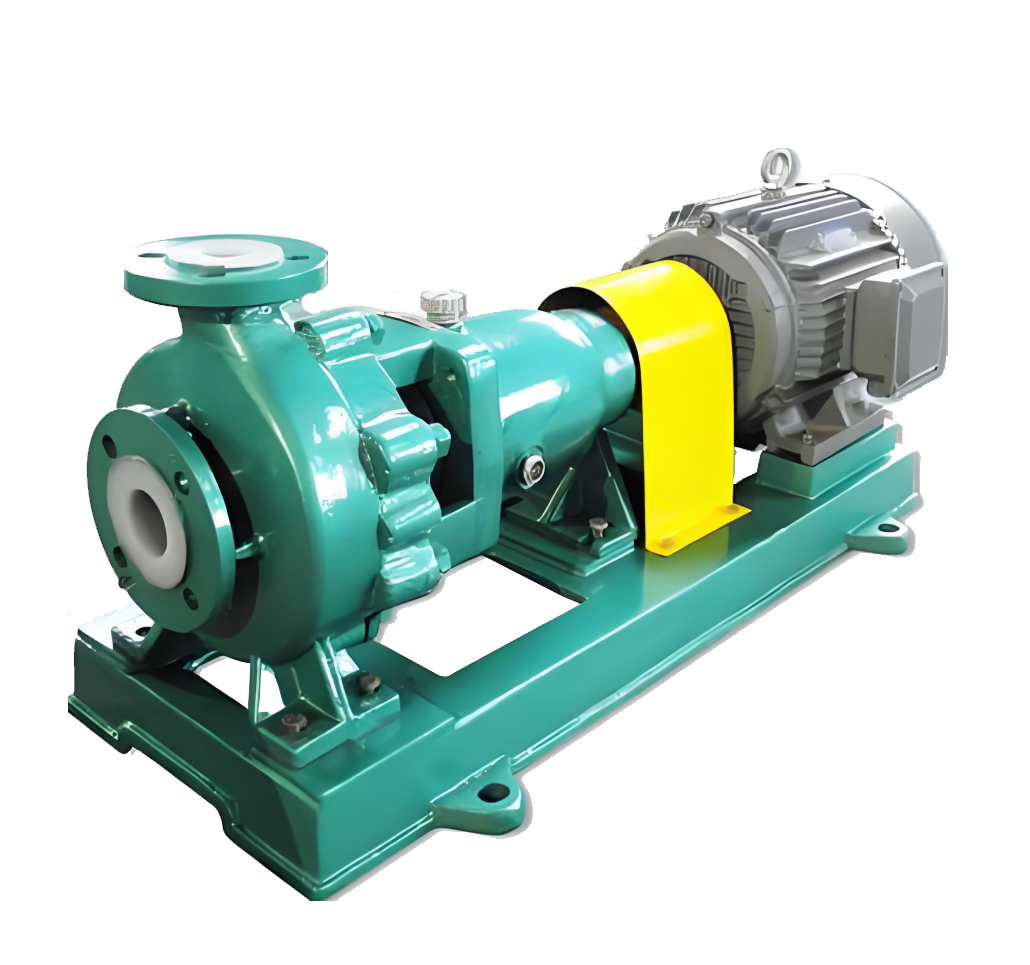

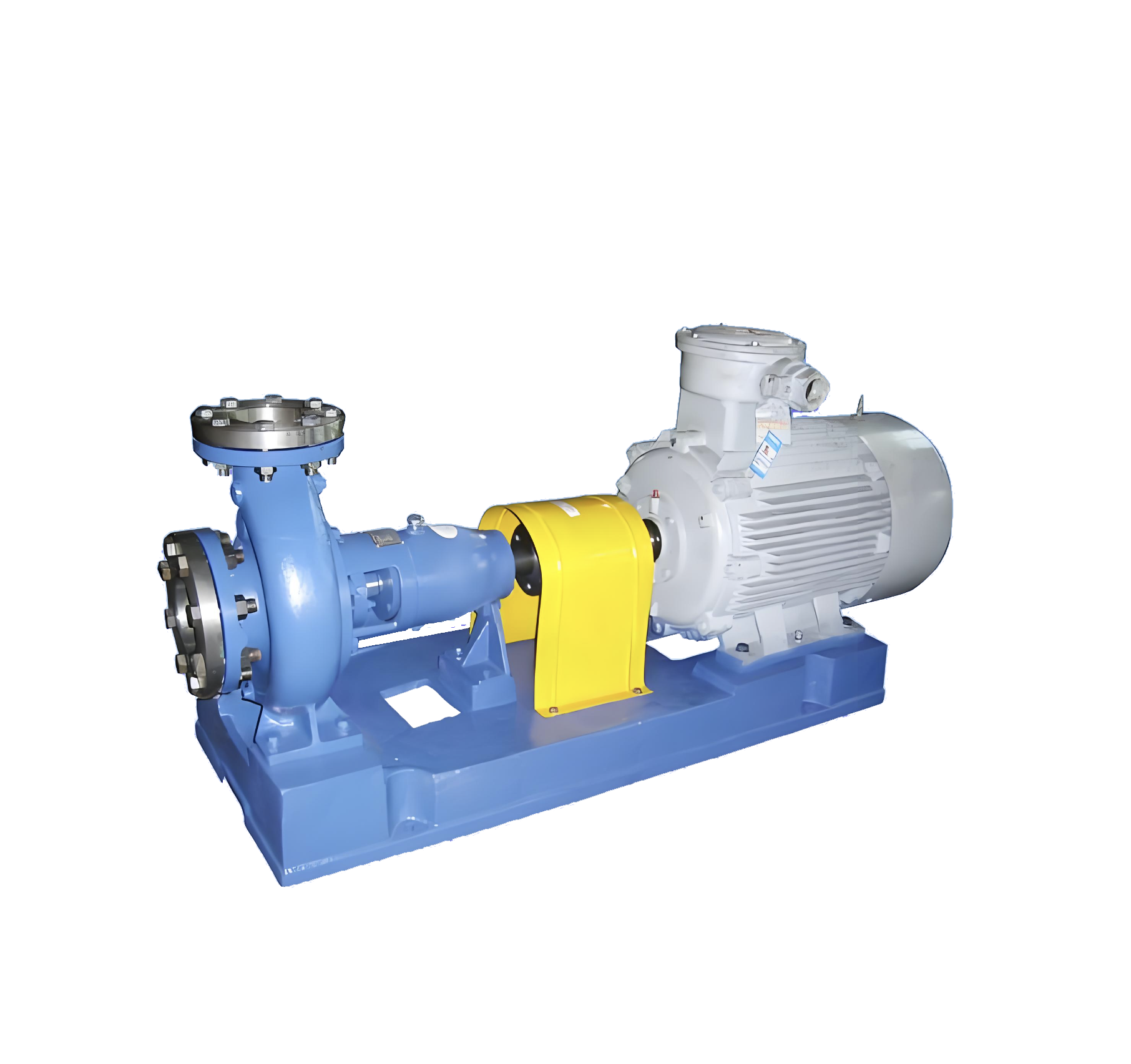

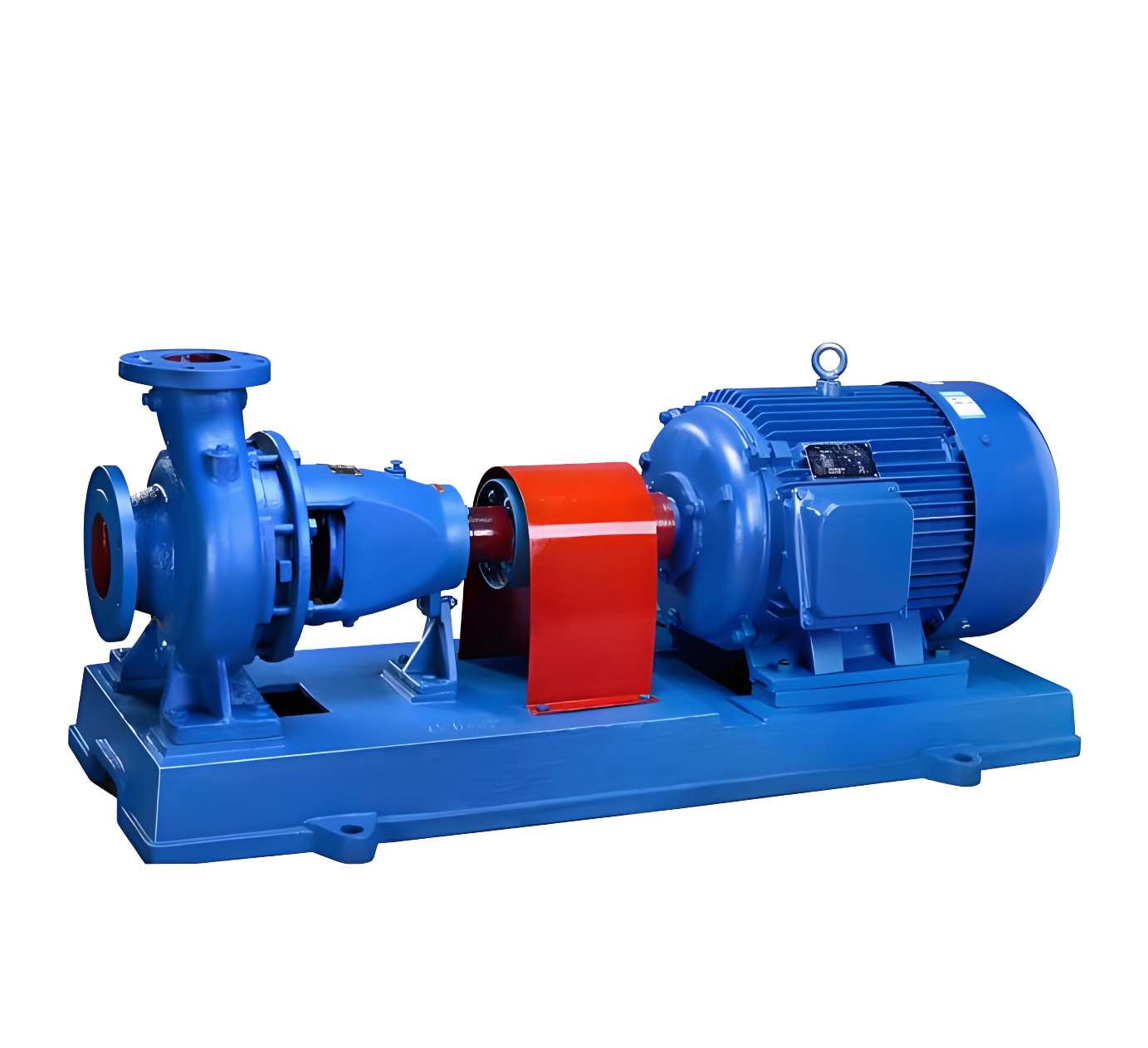

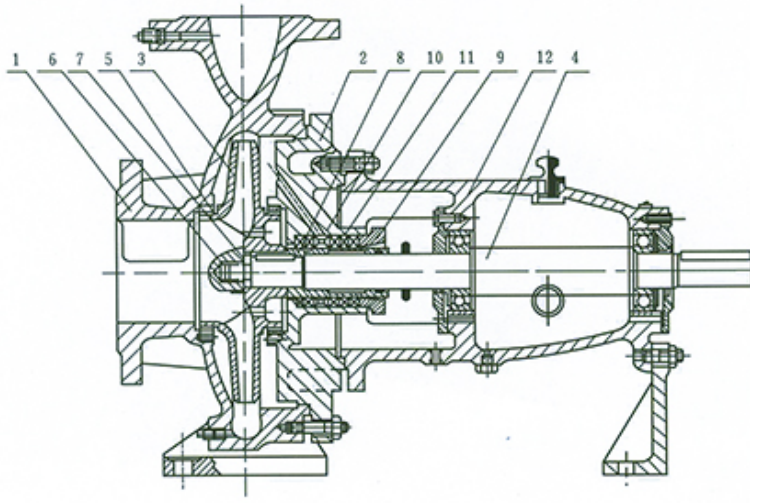

Product diagram of IS clear water and IR hot water single-stage centrifugal pump

The IS and IR pump systems are designed according to the performance and dimensions specified in the international standard ISO2858, and their technical standards are close to international standards and have reached the international advanced level. It is one of the energy-saving pump products promoted in China. This pump has a simple structure, reliable performance, small size, light weight, good anti cavitation performance, low power consumption, and easy use and maintenance. The IS and IR pumps have a wide range of universality, with a total of 140 specifications in the entire series, but only four shafts are used; Shafts, bearings, shaft seals, impeller fasteners, etc. of the same specification can be interchanged; There are only four types of suspension for the entire series of pumps.

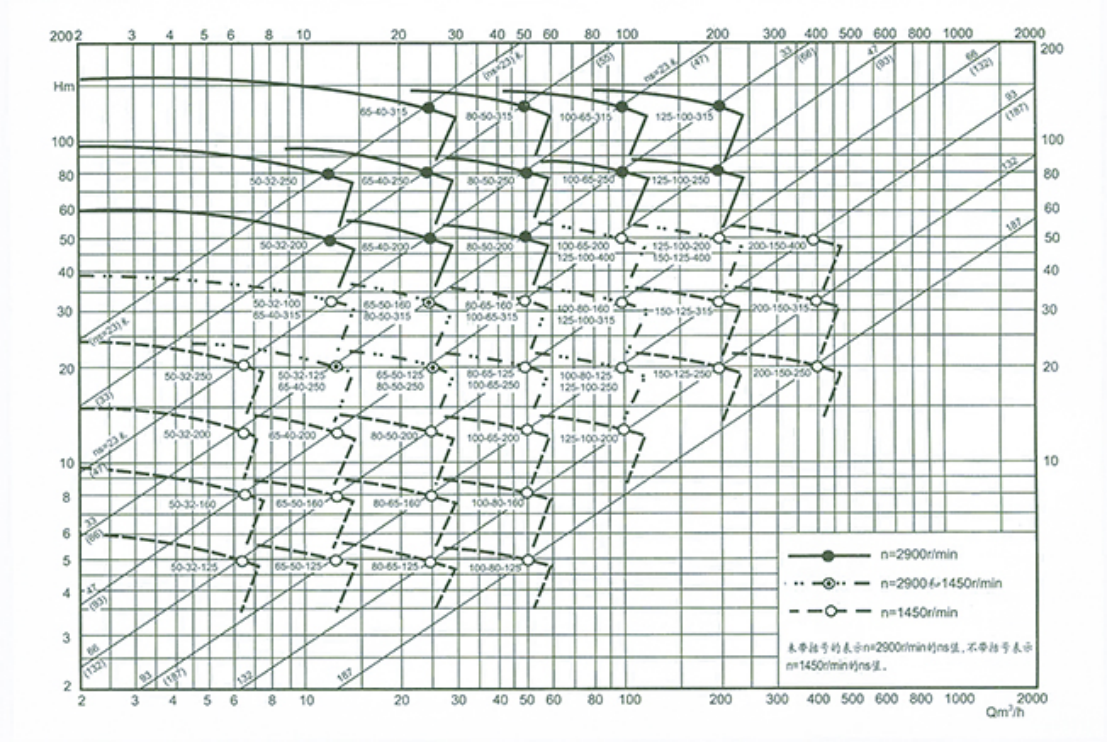

The pump speed is divided into two types: 2900 and 1450 revolutions per minute.

The performance is as follows: 2900 rpm, 1450 rpm

Maximum flow rate: 240 m3/hour, 400 m3/hour

Maximum total lift: 125 meters and 55 meters

Maximum speed: 3500 revolutions per minute (when used for a 60 frequency modulation power supply, the impeller diameter is slightly reduced)

Maximum operating temperature: 80℃

The allowable suction pipeline pressure is 0.3Mpa, and the maximum operating pressure of the pump is 1.6Mpa.

Explanation of Model Meaning

This pump is a rear opening type, and there is no need to disassemble the suction and discharge pipelines when removing the pump cover and impeller. The suspension is equipped with two ball bearings, which are lubricated with machine oil or grease. The pump is directly driven by an electric motor through an elastic coupling. The vortex chamber, feet, inlet flange, and outlet flange are cast as a whole.

Centrifugal pump structure diagram and component names

Component names: 1. Pump body 2. Pump cover 3. Impeller 4. Shaft 5. Sealing ring 6. Impeller nut 7. Stop washer 8. Shaft sleeve 9. Packing cover 10. Packing ring 11. Packing 12. Suspension bearing components

STRUCTURE DESCRIPTION

The IS and IR pump systems are designed according to the performance and dimensions specified in the national standard ISO2858, mainly consisting of the pump body (1), pump cover (2), impeller (3), shaft (4), sealing ring (5), shaft sleeve (8), and suspension bearing components (12).

The pump body and pump cover of IS and IR pumps are divided from the back of the impeller, which is commonly known as the rear opening structure. Its advantage is that it is easy to maintain. During maintenance, the pump body, suction pipeline, discharge pipeline, and motor do not need to be moved. Only the middle connecting piece of the extended coupling needs to be removed to exit the rotor components for maintenance.

The pump casing (i.e. pump body and pump cover) constitutes the working chamber, impeller, shaft, and rolling bearings of the pump, which are the rotor of the pump. The suspension bearing components support the rotor components of the pump, while the rolling bearings bear the radial and axial forces of the pump.

In order to balance the axial force of the pump, most pumps are equipped with sealing rings at the front and rear of the impeller, and balance holes are provided on the rear cover plate of the impeller. Due to the low axial force of some pumps, there are no sealing rings or balance holes on the back of the impeller.

The axial sealing ring of the pump is composed of a packing gland (9), packing ring (10), and packing (11), etc., to prevent air intake or significant water leakage. If the impeller of the pump is balanced, the cavity containing soft packing is connected to the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to introduce air along the surface of the shaft sleeve. Therefore, a packing ring is installed in the packing chamber to guide the pressure water in the pump chamber to the packing ring through the small hole on the pump cover for sealing. If the impeller of the pump does not have a balance hole, there is no leakage problem due to the liquid pressure on the back of the impeller being greater than atmospheric pressure, so the packing ring can be omitted.

To avoid shaft wear, a shaft sleeve is installed at the part where the shaft passes through the packing chamber for protection. A O-ring seal is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface.

The transmission mode of the pump is connected to the electric motor through an extended elastic coupling. The rotation direction of the pump, when viewed from the drive end, is clockwise.

Spectral diagram of IS and IR pump types

Model and Performance Parameter Table

| 型 号 model | 转速n(r/min) | 流量Q | 扬程H(m) | 效率η(%) | 功率(KW) | 必需气蚀余量r(m) | 叶轮名义直径(mm) | 可代替老 产品型号 | ||

| (m3/h) | (L/S) | 轴功率 | 电机功率 | |||||||

| 50-32-125 | 2900 | 7.512.515 | 2.083.474.17 | 20 | 60 | 1.13 | 2.2 | 2.0 | 130 | 12(1)BA-612(1)B-17 |

| 1450 | 3.756.37.5 | 1.041.742.08 | 5 | 54 | 0.16 | 0.55 | 2.0 | |||

| 50-32-125A | 2900 | 6.7211.213.4 | 1.863.113.74 | 16 | 60 | 0.81 | 1.1 | 116.5 | 12(1)BA-6A | |

| 1450 | 3.365.66.7 | 0.931.561.86 | 4 | 54 | 0.04 | 0.22 | 12(1)B-17A | |||

| 50-32-160 | 2900 | 7.512.515 | 2.083.474.17 | 32 | 54 | 2.02 | 3 | 2.0 | 158 | |

| 1450 | 3.756.37.5 | 1.041.742.08 | 8 | 48 | 0.29 | 0.55 | 2.0 | 2DA-8×4 | ||

| 50-32-160A | 2900 | 7.0211.714 | 1.953.253.9 | 28 | 2.2 | 148 | 2DA-8×3 | |||

| 1450 | 3.515.07.02 | 0.971.641.95 | 7 | 48 | 0.23 | 0.40 | 2.0 | |||

| 50-32-160B | 2900 | 6.510.813 | 1.813.013.62 | 24 | 54 | 1.32 | 1.5 | 137 | ||

| 1450 | 3.255.46.5 | 1.5 | 6 | 48 | 0.17 | 0.22 | ||||

| 50-32-200 | 2900 | 7.512.515 | 2.083.474.17 | 50 | 48 | 3.45 | 5.5 | 2.0 | 198 | 2DA-8×6 |

| 1450 | 3.756.37.5 | 1.041.742.08 | 12.5 | 42 | 0.51 | 0.75 | 2.0 | |||

| 50-32-200A | 2900 | 7.0211.714 | 1.953.253.9 | 44 | 48 | 2.91 | 4 | 2.0 | 185.5 | 2DA-8×5 |

| 1450 | 3.515.97.02 | 0.971.641.95 | 11 | 42 | 0.33 | 0.55 | 2.0 | |||

| 50-32-200B | 2900 | 6.5310.813.1 | 1.813.013.63 | 38 | 48 | 2.34 | 3 | 2.0 | 172.5 | 2DA |

| 1450 | 3.265.46.53 | 0.911.51.81 | 9.5 | 42 | 0.42 | 0.55 | 2.0 | |||

| 50-32-250 | 2900 | 7.512.5150 | 2.083.474.17 | 80 | 38 | 7.16 | 11 | 2.0 | 250 | 40D40×2 |

| 1450 | 3.756.37.5 | 1.041.742.08 | 20 | 32 | 1.07 | 1.5 | 2.0 | 2DA-8×9 | ||

| 50-32-250A | 2900 | 7.0211.714 | 1.953.253.9 | 70 | 38 | 5.87 | 7.5 | 2.0 | 234 | 2DA-8×8 |

| 1450 | 3.515.96.53 | 0.971.641.81 | 17.5 | 32 | 0.88 | 1.5 | 2.0 | |||

| 50-32-250B | 2900 | 65.310.813.1 | 1.813.013.63 | 60 | 38 | 4.65 | 5.5 | 2.0 | 216.5 | 2DA-8×7 |

| 1450 | 3.265.46.53 | 0.911.51.81 | 15 | 32 | 0.69 | 1.1 | 2.0 | |||

| 65-50-125 | 2900 | 152530 | 4.176.948.33 | 20 | 69 | 1.97 | 3 | 2.0 | 130 | 2BA-19 |

| 1450 | 7.512.515 | 2.083.474.17 | 5 | 64 | 0.27 | 0.55 | 2B19 | |||

| 65-50-125A | 2900 | 13.422.426.9 | 3.736.227.46 | 16 | 69 | 1.42 | 2.2 | 2.0 | 116.5 | 2BA-9A |

| 1450 | 6.7211.213.4 | 1.863.113.73 | 4 | 64 | 0.19 | 0.22 | 2.0 | 2B19A | ||

| 65-50-160 | 2900 | 152530 | 4.176.948.33 | 32 | 65 | 3.35 | 5.5 | 2.0 | 158.5 | 2BA-6 |

| 1450 | 7.512.515 | 2.083.474.17 | 8 | 60 | 0.45 | 0.75 | 2.0 | 2B31 | ||

| 65-50-160A | 2900 | 1423.428 | 3.896.56.48 | 28 | 65 | 2.73 | 4 | 2.0 | 148 | 2BA-6A |

| 1450 | 711.714 | 1.943.253.89 | 7 | 60 | 0.37 | 0.55 | 2.0 | 2B31A | ||

| 65-50-160B | 2900 | 1321.726 | 3.626.037.23 | 24 | 65 | 2.19 | 3 | 2.0 | 137.5 | 2BA-6B |

| 1450 | 6.510.813 | 1.83.013.62 | 6 | 60 | 0.29 | 0.40 | 2.0 | 2B31B | ||

| 65-40-200 | 2900 | 152530 | 4.176.948.33 | 50 | 60 | 5.67 | 7.5 | 2.0 | 200 | 50D-8×6 |

| 1450 | 7.512.515 | 2.083.474.17 | 12.5 | 55 | 0.77 | 1.1 | 2.0 | |||

| 65-40-200A | 2900 | 1423.428 | 3.896.56.48 | 44 | 60 | 4.67 | 5.5 | 2.0 | 187.5 | 50D-8×5 |

| 1450 | 711.714 | 1.943.253.89 | 11 | 55 | 0.63 | 0.75 | 2.0 | |||

| 65-40-200B | 2900 | 1321.726 | 3.626.037.23 | 38 | 60 | 3.76 | 4 | 2.0 | 174.5 | 50D-8×4 |

| 1450 | 6.510.813 | 1.83.013.62 | 9.5 | 55 | 0.51 | 0.55 | 2.0 | |||

| 65-40-250 | 2900 | 152530 | 4.176.948.33 | 80 | 50 | 10.89 | 15 | 2.0 | 254 | 2DA-8×9 |

| 1450 | 7.512.515 | 2.083.474.17 | 20 | 46 | 1.48 | 2.2 | 2.0 | |||

| 65-40-250A | 2900 | 1423.428 | 3.806.56.48 | 70 | 53 | 8.42 | 11 | 2.0 | 237.5 | 50D-8×9 |

| 1450 | 711.714 | 1.943.253.89 | 17.5 | 48 | 1.17 | 2.2 | 2.0 | |||

| 65-40-250B | 2900 | 13.21.726 | 3.626.037.23 | 60 | 53 | 6.7 | 7.5 | 2.0 | 220 | 50D-8×7 |

| 1450 | 6.510.813 | 1.83.013.62 | 15 | 48 | 0.9 | 1.1 | 2.0 | |||

| 65-40-315 | 2900 | 152530 | 4.176.948.33 | 125 | 50 | 21.3 | 30 | 2.5 | 315 | 50D-32×4 |

| 1450 | 7.512.515 | 2.083.474.17 | 32 | 37 | 2.94 | 4 | 2.5 | |||

| 65-40-315A | 2900 | 14.323.928.7 | 3.986.647.96 | 114 | 40 | 18.6 | 22 | 2.5 | 301 | |

| 1450 | 7.1711.914.3 | 1.993.323.98 | 28.5 | 37 | 2.57 | 4 | 2.5 | |||

| 65-40-315B | 2900 | 13.622.727.2 | 3.786.37.56 | 103 | 40 | 15.9 | 18.5 | 2.5 | 286 | 50D-32×3 |

| 1450 | 6.811.313.6 | 1.893.153.78 | 25.8 | 37 | 2.2 | 3 | 2.5 | |||

| 65-40-315C | 2900 | 12.821.452.7 | 3.575.947.14 | 92 | 40 | 11.5 | 15 | 2.5 | ||

| 1450 | 6.4310.712.8 | 1.782.973.57 | 23 | 37 | 1.85 | 2.2 | 2.5 | 270 | ||

| 80-65-125 | 2900 | 305060 | 8.3813.916.7 | 20 | 75 | 3.6 | 5.5 | 3.0 | 137 | 3BA-3 |

| 1450 | 152530 | 4.176.948.33 | 5 | 71 | 0.48 | 0.75 | 2.5 | 3B19 | ||

| 80-65-125A | 2900 | 27.344.754.5 | 7.5712.415.2 | 16 | 75 | 2.72 | 4 | 3.0 | 124.5 | 3BA-13A |

| 1450 | 13.622.427.3 | 3.796.227.57 | 4 | 71 | 0.36 | 0.55 | 2.5 | 3B19A | ||

| 80-65-160 | 2900 | 305060 | 8.3313.916.7 | 32 | 73 | 5.97 | 7.5 | 2.5 | 168 | 3BA-9 |

| 1450 | 152530 | 4.176.948.33 | 8 | 69 | 0.79 | 1.5 | 2.5 | 3B33 | ||

| 80-65-160A | 2900 | 2846.856 | 7.781315.6 | 28 | 73 | 4.87 | 5.5 | 2.5 | 157 | 3BA-9A |

| 1450 | 1423.428 | 3.96.57.78 | 7 | 69 | 0.64 | 0.75 | 2.5 | 3B33A | ||

| 80-65-160B | 2900 | 2643.352 | 7.211214.5 | 24 | 73 | 3.36 | 4 | 2.5 | 145.5 | 3BA-9B |

| 1450 | 1321.726 | 3.66.037.21 | 6 | 69 | 0.51 | 0.55 | 2.5 | 2B33B | ||

| 80-50-200 | 2900 | 305060 | 8.3313.916.7 | 50 | 69 | 9.87 | 15 | 2.5 | 202 | 3BA-6 |

| 1450 | 152530 | 4.176.948.33 | 125 | 65 | 1.31 | 2.2 | 2.5 | 3B57 | ||

| 80-50-200A | 2900 | 28.146.856.3 | 7.821315.7 | 44 | 69 | 8.15 | 11 | 2.5 | 189.5 | 3BA-6A |

| 1450 | 14.123.428.1 | 3.916.57.82 | 11 | 65 | 1.08 | 1.5 | 2.5 | 3B57A | ||

| 80-50-200B | 2900 | 26.143.352.3 | 7.621214.6 | 38 | 69 | 6.53 | 7.5 | 2.5 | 176 | 3BA-6B |

| 1450 | 13.121.726.1 | 3.636.037.26 | 9.5 | 65 | 0.87 | 1.1 | 2.5 | 3B57B | ||

| 80-50-250 | 2900 | 305060 | 8.3313.916.7 | 80 | 63 | 17.3 | 22 | 2.5 | 250 | 100D-16×5 |

| 1450 | 152530 | 4.176.948.33 | 20 | 60 | 2.27 | 3 | 2.5 | 4DA-8×5 | ||

| 80-50-250A | 2900 | 28.146.856.3 | 7.821315.7 | 70 | 63 | 14.2 | 18.5 | 2.5 | 234 | |

| 1450 | 14.123.423.1 | 3.916.57.82 | 17.5 | 60 | 1.86 | 3 | 2.5 | |||

| 80-50-250B | 2900 | 26.143.352.3 | 7.261214.6 | 60 | 63 | 11.2 | 15 | 2.5 | 216.5 | 100D-16×4 |

| 1450 | 13.121.726.1 | 3.636.037.26 | 15 | 60 | 1.47 | 2.2 | 2.5 | 4DA-8×4 | ||

| 80-50-315 | 2900 | 305060 | 8.3313.916.7 | 125 | 54 | 31.5 | 37 | 2.5 | 315 | 100D-16×8 |

| 1450 | 152530 | 4.176.948.33 | 32 | 52 | 4.19 | 5.5 | 2.5 | 4DA-8×8 | ||

| 80-50-315A | 2900 | 28.747.757.3 | 7.9613.315.9 | 114 | 54 | 26.3 | 30 | 2.5 | 301 | 100D-16×6 |

| 1450 | 14.323.828.7 | 3.986.627.96 | 28.5 | 52 | 3.66 | 5.5 | 2.5 | 4DA-8×6 | ||

| 80-50-315B | 2900 | 27.245.454.5 | 7.5612.615.2 | 103 | 54 | 23.6 | 30 | 2.5 | 286 | |

| 1450 | 13.622.727.2 | 3.796.37.56 | 25.8 | 52 | 3.14 | 5.5 | 2.5 | |||

| 80-50-315C | 2900 | 25.742.951.4 | 7.1411.914.3 | 92 | 54 | 17 | 22 | 2.5 | 270 | |

| 1450 | 12.921.425.7 | 3.575.947.14 | 23 | 2.63 | 4 | 2.5 | ||||

| 100-80-125 | 2900 | 60100120 | 16.727.833.3 | 20 | 78 | 7.0 | 11 | 4.5 | 139 | 4BA-18 |

| 1450 | 305060 | 8.3313.916.7 | 5 | 75 | 0.91 | 1.5 | 2.5 | 4B20 | ||

| 100-80-125A | 2900 | 53.789.4107 | 1524.829.8 | 16 | 78 | 5.03 | 7.5 | 4.5 | 124.5 | 4BA-18A |

| 1450 | 26.944.753.7 | 7.4612.415 | 4 | 75 | 0.65 | 0.75 | 2.5 | 4B20A | ||

| 100-80-160 | 2900 | 60100120 | 16.727.833.3 | 32 | 78 | 11.2 | 15 | 4.0 | 170 | 4BA-12 |

| 1450 | 305060 | 8.3313.916.7 | 8 | 75 | 1.45 | 2.2 | 2.5 | 4B35 | ||

| 100-80-160A | 2900 | 56.193.5112 | 15.62631.1 | 28 | 78 | 9.16 | 11 | 4.0 | 159 | 4BA-12A |

| 1450 | 2846.856.1 | 7.791315.6 | 7 | 75 | 1.19 | 1.5 | 2.5 | 4B35A | ||

| 100-80-160B | 2900 | 5083.5100 | 13.923.228 | 22.3 | 78 | 6.95 | 7.5 | 4.0 | 142 | 4BA-12B |

| 1450 | 2541.850 | 6.8611.613.9 | 5.6 | 75 | 0.85 | 1.1 | 2.5 | 4B35B | ||

| 100-65-200 | 2900 | 60100120 | 16.727.833.3 | 50 | 76 | 17.9 | 22 | 3.6 | 203 | 4BA-8A |

| 1450 | 305060 | 8.3313.916.7 | 12.5 | 73 | 2.33 | 4 | 2.0 | 4B60A | ||

| 100-65-200A | 2900 | 56.193.5112 | 15.62631.1 | 44 | 76 | 14.2 | 18.5 | 190.5 | 4BA-8B | |

| 1450 | 2846.856.1 | 7.791315.6 | 11 | 73 | 1.93 | 3 | 4B60B | |||

| 100-65-200B | 2900 | 52.386.610.5 | 14.624.129 | 38 | 9.94 | 15 | 177 | |||

| 1450 | 26.243.352.3 | 7.261214.6 | 9.5 | 1.54 | 2.2 | |||||

| 100-65-250 | 2900 | 60100120 | 16.727.833.3 | 80 | 72 | 30.3 | 37 | 3.8 | 255 | DA1-125×4 |

| 1450 | 305060 | 8.3313.916.7 | 20 | 68 | 4.0 | 5.5 | 2.0 | |||

| 100-65-250A | 2900 | 56.193.5112 | 15.62631.1 | 70 | 72 | 24.8 | 30 | 3.8 | 238.5 | |

| 1450 | 2846.856.1 | 7.791315.6 | 17.5 | 68 | 3.27 | 4 | 2.0 | |||

| 100-65-250B | 2900 | 52.386.6105 | 14.624.129 | 60 | 72 | 19.7 | 22 | 3.8 | 221 | DA1-125×3 |

| 1450 | 26.243.352.3 | 7.261214.6 | 15 | 68 | 2.6 | 3 | 2.0 | |||

| 100-65-315 | 2900 | 60100120 | 16.727.833.3 | 125 | 66 | 51.6 | 75 | 3.6 | 315.5 | 125D-25×5 |

| 1450 | 305060 | 8.3313.916.7 | 32 | 63 | 6.92 | 11 | 2.0 | |||

| 100-65-315A | 2900 | 57.395.5114 | 1626.531.8 | 114 | 66 | 45 | 55 | 3.6 | 301.5 | |

| 1450 | 28.747.757.3 | 7.9613.316 | 28.5 | 63 | 6.03 | 7.5 | 2.0 | |||

| 100-65-315B | 2900 | 54.590.8109 | 15.225.230.2 | 103 | 66 | 38.6 | 45 | 3.6 | 286.5 | 125D-25×4 |

| 1450 | 27.245.454.5 | 7.5612.615.2 | 25.8 | 63 | 5.18 | 7.5 | 2.0 | |||

| 100-65-315C | 2900 | 51.485.8103 | 14.323.828.6 | 92 | 66 | 32.5 | 37 | 3.6 | 270.5 | |

| 1450 | 25.742.951.4 | 7.1411.914.3 | 23 | 63 | 4.36 | 5.5 | 2.0 | |||

| 125-100-200 | 2900 | 120200240 | 33.355.666.7 | 50 | 81 | 33.6 | 45 | 4.5 | 216 | 150S-50 |

| 1450 | 60100120 | 16.727.833.3 | 12.5 | 76 | 4.48 | 7.5 | 2.5 | 6Sh-9 | ||

| 125-100-200A | 2900 | 113187225 | 31.25262.5 | 44 | 81 | 27.7 | 37 | 4.5 | 202.5 | 150S-50A |

| 1450 | 56.393.5113 | 15.72631.2 | 11 | 76 | 3.69 | 5.5 | 2.5 | 6Sh-9A | ||

| 125-100-200B | 2900 | 105173209 | 29.148.158.2 | 38 | 81 | 22.3 | 30 | 4.5 | 188.5 | 150S-50B |

| 1450 | 52.486.5105 | 14.624.129.1 | 9.5 | 76 | 2.98 | 4 | 2.5 | |||

| 125-100-250 | 2900 | 120200240 | 33.355.666.7 | 80 | 78 | 55.9 | 75 | 4.2 | 255 | 150S-78 |

| 1450 | 60100120 | 16.727.833.3 | 20 | 76 | 7.17 | 11 | 2.5 | |||

| 125-100-250A | 2900 | 113187225 | 31.25262.5 | 70 | 78 | 45.7 | 55 | 238.5 | ||

| 1450 | 56.393.5113 | 15.72631.2 | 17.5 | 75 | 5.87 | 7.5 | ||||

| 1250-100-250B | 2900 | 105173209 | 29.148.158.2 | 60 | 78 | 36.4 | 45 | 221 | ||

| 1450 | 52.486.5105 | 14.624.129.1 | 15 | 76 | 4.67 | 5.5 | ||||

| 125-100-315 | 2900 | 120200240 | 33.355.666.7 | 125 | 75 | 90.8 | 110 | 4.5 | 317 | D155-30×4 |

| 1450 | 60100120 | 16.727.833.3 | 32 | 73 | 11.9 | 15 | 2.2 | 150D-30×3 | ||

| 125-100-315A | 2900 | 115191229 | 31.853.163.6 | 114 | 75 | 78.9 | 90 | 302.5 | ||

| 1450 | 57.395.515 | 15.926.531.8 | 28.5 | 73 | 10.3 | 15 | ||||

| 125-100-315B | 2900 | 109182218 | 30.250.460.6 | 103 | 75 | 68.1 | 75 | 288 | ||

| 1450 | 54.590.8109 | 15.225.230.2 | 25.8 | 73 | 8.92 | 11 | ||||

| 125-100-315C | 2900 | 103172206 | 28.647.757.2 | 92 | 75 | 57.4 | 75 | 272 | ||

| 1450 | 51.485.8103 | 14.323.828.6 | 23 | 73 | 7.5 | 11 | ||||

| 125-100-400 | 1450 | 60100120 | 16.727.833.3 | 50 | 65 | 21 | 30 | 2.5 | 395 | |

| 125-100-400A | 1450 | 56.393.5113 | 15.72631.2 | 44 | 65 | 17.3 | 22 | 2.5 | 370.5 | |

| 125-100-400B | 1450 | 52.486.5150 | 14.62429.1 | 38 | 65 | 13.9 | 18.5 | 2.5 | 344.5 | |

| 150-125-250 | 1450 | 120200240 | 33.355.666.7 | 20 | 81 | 13.5 | 18.5 | 3.0 | 260 | 6BA-126B20 |

| 150-125-250A | 1450 | 113187225 | 31.25262.5 | 17.5 | 81 | 11.1 | 15 | 3.0 | 243.5 | 6BA-12A6B20A |

| 150-125-250B | 1450 | 105173209 | 29.148.158.2 | 15 | 81 | 8.75 | 11 | 3.0 | 225 | 6BA-12B6B20B |

| 150-125-315 | 1450 | 120200240 | 33.355.666.7 | 32 | 79 | 21.08 | 30 | 2.5 | 325 | 6BA-86B33 |

| 150-125-315A | 1450 | 113187225 | 31.25262.5 | 28 | 80 | 17.8 | 22 | 2.5 | 304 | 6BA-8A6B33A |

| 150-125-315B | 1450 | 105173209 | 29.148.158.2 | 24 | 80 | 14.2 | 18.5 | 2.5 | 281.5 | 6BA-8B6B33B |

| 150-125-400 | 1450 | 120200240 | 33.355.666.7 | 50 | 75 | 36.3 | 45 | 2.8 | 399.5 | |

| 150-125-400A | 1450 | 113187225 | 31.25262.5 | 44 | 75 | 29.9 | 37 | 2.8 | 374.5 | |

| 150-125-400B | 1450 | 113187225 | 31.25262.5 | 38 | 75 | 24.1 | 30 | 2.8 | 348.5 | |

| 200-150-250 | 1450 | 240400460 | 66.7111.1128 | 20 | 82 | 26.6 | 37 | 4.2 | 275 | 8BA-188B18 |

| 200-150-250A | 1450 | 225374431 | 62.5104120 | 17.5 | 82 | 21.8 | 30 | 4.2 | 257.5 | 8BA-18A8B18A |

| 200-150-250B | 1450 | 208346398 | 57.796.2111 | 15 | 82 | 17.2 | 22 | 4.2 | 238 | 8BA-18B8B18B |

| 200-150-315 | 1450 | 240400460 | 66.7111128 | 32 | 82 | 42.5 | 55 | 3.5 | 346 | 8BA-12 |

| 200-150-315A | 1450 | 225374431 | 62.5104120 | 28 | 82 | 35.4 | 45 | 3.5 | 325.5 | 8BA-12A |

| 200-150-315B | 1450 | 208346398 | 57.796.2111 | 24 | 82 | 27.9 | 37 | 301.5 | 8BA-12B | |

| 200-150-400 | 1450 | 240400460 | 66.7111128 | 50 | 81 | 67.2 | 90 | 3.8 | 395 | |

| 200-150-400A | 1450 | 225374431 | 62.5104120 | 44 | 81 | 55.5 | 75 | 3.8 | 370.5 | |

| 200-150-400B | 1450 | 208346398 | 57.796.2111 | 38 | 81 | 44.6 | 55 | 3.8 | 344.5 | |

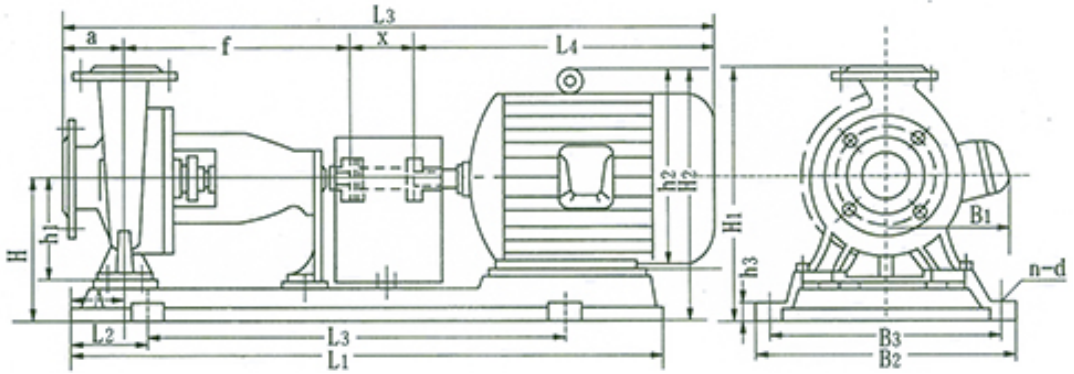

IS clear water centrifugal pump, IR hot water centrifugal pump

Outline installation dimension diagram

Outline installation dimension table

| 产品型号PRODUCT MODEL | 机座号/功率Machine base number/power | |||||||||||||||||||

| A | L1 | L2 | L3 | L4 | a | f | X | L5 | B1 | B2 | B3 | h1 | h2 | h3 | H | H1 | H2 | n-d | ||

| 50-32-125 | 80-4/0.55 | 80 | 820 | 150 | 540 | 285 | 80 | 385 | 100 | 850 | 150 | 360 | 320 | 112 | 170 | 25 | 237 | 377 | 327 | 4-ф18.5 |

| 80-2/1.1 | 310 | 875 | 115 | |||||||||||||||||

| 90S-2/1.5 | 920 | 170 | 600 | 335 | 190 | 337 | ||||||||||||||

| 90L-2/2.2 | 900 | 390 | 350 | |||||||||||||||||

| 50-32-160 | 80-4/0.55 | 80 | 820 | 150 | 540 | 285 | 80 | 385 | 100 | 850 | 150 | 360 | 320 | 132 | 170 | 25 | 257 | 417 | 347 | 4-ф18.5 |

| 90S-2/1.5 | 310 | 875 | 155 | 190 | 357 | |||||||||||||||

| 90L-2/2.2 | 920 | 170 | 600 | 335 | 900 | 390 | 350 | |||||||||||||

| 100L-2/3 | 380 | 945 | 180 | 245 | 402 | |||||||||||||||

| 50-32-200 | 80-4/0.75 | 80 | 820 | 150 | 540 | 285 | 80 | 385 | 100 | 850 | 150 | 360 | 320 | 160 | 170 | 25 | 285 | 465 | 375 | 4-ф18.5 |

| 100L-2/3 | 920 | 170 | 600 | 380 | 945 | 180 | 390 | 350 | 245 | 430 | ||||||||||

| 112M-2/4 | 400 | 965 | 190 | 265 | 438 | |||||||||||||||

| 132S-2/5.5 | 1020 | 190 | 600 | 475 | 1040 | 210 | 450 | 400 | 315 | 30 | 468 | 4-ф24 | ||||||||

| 50-32-250 | 90S-4/1.1 | 95 | 1020 | 190 | 660 | 310 | 100 | 500 | 100 | 1010 | 155 | 450 | 400 | 180 | 190 | 30 | 305 | 530 | 450 | 4-ф24 |

| 90L-4/1.5 | 335 | 1035 | 315 | 320 | 545 | 503 | ||||||||||||||

| 132S-2/2.7 | 1160 | 210 | 740 | 475 | 1175 | 310 | 490 | 440 | ||||||||||||

| 160M-2/11 | 1290 | 225 | 840 | 600 | 1300 | 255 | 540 | 490 | 385 | 340 | 565 | 565 | ||||||||

| 65-50-125 | 80-4/0.55 | 80 | 820 | 150 | 540 | 285 | 80 | 385 | 100 | 850 | 150 | 360 | 320 | 112 | 170 | 25 | 237 | 377 | 327 | 4-ф18.5 |

| 90S-2/1.5 | 310 | 875 | 155 | 190 | 337 | |||||||||||||||

| 90L-2/2.2 | 920 | 170 | 600 | 335 | 900 | 390 | 350 | |||||||||||||

| 100L-2/3 | 380 | 945 | 180 | 245 | 382 | |||||||||||||||

| 65-50-160 | 80-4/0.75 | 80 | 820 | 150 | 540 | 285 | 80 | 385 | 100 | 850 | 150 | 360 | 320 | 132 | 170 | 25 | 257 | 417 | 347 | 4-ф18.5 |

| 100L-2/3 | 920 | 170 | 600 | 380 | 945 | 180 | 390 | 350 | 245 | 402 | ||||||||||

| 112M-2/4 | 400 | 965 | 190 | 265 | 410 | |||||||||||||||

| 132S-2/5.5 | 1020 | 190 | 660 | 475 | 1040 | 210 | 450 | 400 | 315 | 30 | 440 | 4-ф24 | ||||||||

| 65-40-200 | 80-4/0.75 | 80 | 920 | 170 | 600 | 285 | 100 | 385 | 100 | 870 | 150 | 390 | 350 | 160 | 170 | 25 | 285 | 465 | 375 | 4-ф18.5 |

| 90S-4/1.1 | 310 | 895 | 155 | 190 | 385 | |||||||||||||||

| 112M-2/4 | 400 | 985 | 190 | 265 | 438 | |||||||||||||||

| 132S-2/7.5 | 1020 | 190 | 660 | 475 | 1060 | 210 | 450 | 400 | 315 | 30 | 468 | 4-ф24 | ||||||||

| 65-40-250 | 90S-4/1.1 | 95 | 1020 | 190 | 660 | 310 | 100 | 500 | 100 | 1010 | 155 | 450 | 400 | 180 | 190 | 30 | 305 | 530 | 405 | 4-ф24 |

| 90L-4/1.5 | 335 | 1035 | ||||||||||||||||||

| 100L-4/2.2 | 1160 | 210 | 740 | 380 | 1080 | 180 | 245 | 450 | ||||||||||||

| 132S-2/7.5 | 1290 | 225 | 840 | 475 | 1175 | 210 | 490 | 440 | 315 | 320 | 545 | 503 | ||||||||

| 160M-2/15 | 600 | 1300 | 255 | 540 | 490 | 285 | 340 | 656 | 565 | |||||||||||

| 65-40-315 | 100L-4/3 | 95 | 1140 | 210 | 740 | 380 | 125 | 500 | 100 | 1105 | 180 | 490 | 440 | 200 | 245 | 30 | 340 | 590 | 485 | 4-ф24 |

| 112M-4/4 | 400 | 1125 | 190 | 265 | 492 | |||||||||||||||

| 160L-2/18.5 | 1290 | 225 | 840 | 645 | 1370 | 255 | 540 | 490 | 385 | 360 | 610 | 585 | ||||||||

| 180M-2/22 | 670 | 1395 | 285 | 460 | 610 | |||||||||||||||

| 200L-2/30 | 1420 | 250 | 940 | 775 | 1500 | 310 | 610 | 550 | 475 | 380 | 630 | 655 | 4-ф28 | |||||||

| 80-65-125 | 80-4/0.75 | 80 | 820 | 150 | 540 | 285 | 100 | 385 | 100 | 870 | 150 | 360 | 320 | 132 | 170 | 40 | 257 | 417 | 347 | 4-ф18.5 |

| 100L-2/3 | 920 | 170 | 600 | 380 | 965 | 180 | 390 | 350 | 245 | 25 | 402 | |||||||||

| 112M-2/4 | 400 | 985 | 190 | 265 | 410 | |||||||||||||||

| 132S-2/5.5 | 1020 | 190 | 660 | 475 | 1060 | 210 | 450 | 400 | 315 | 30 | 440 | 4-ф24 | ||||||||

| 80-65-160 | 80-4/0.75 | 80 | 920 | 170 | 600 | 285 | 100 | 385 | 100 | 870 | 150 | 390 | 350 | 160 | 170 | 30 | 285 | 465 | 375 | 4-ф18.5 |

| 90S-4/1.1 | 310 | 895 | 155 | 190 | 385 | |||||||||||||||

| 90L-4/1.5 | 335 | 920 | ||||||||||||||||||

| 112M-2/4 | 400 | 985 | 190 | 265 | 438 | |||||||||||||||

| 132S-2/7.5 | 1020 | 190 | 660 | 475 | 1060 | 210 | 450 | 400 | 315 | 30 | 468 | 4-ф24 | ||||||||

| 80-50-200 | 90S-4/1.1 | 80 | 920 | 170 | 600 | 310 | 100 | 385 | 100 | 895 | 155 | 390 | 350 | 160 | 190 | 25 | 285 | 485 | 385 | 4-ф18.5 |

| 90L-4/1.5 | 335 | 920 | ||||||||||||||||||

| 100L-4/2.2 | 380 | 965 | 180 | 245 | 430 | |||||||||||||||

| 132S-2/7.5 | 1020 | 190 | 660 | 475 | 1060 | 210 | 450 | 400 | 315 | 468 | ||||||||||

| 160M-2/15 | 1140 | 210 | 740 | 600 | 1185 | 255 | 190 | 440 | 385 | 30 | 300 | 500 | 525 | 4-ф24 | ||||||

| 80-50-250 | 100L-4/3 | 95 | 1020 | 190 | 660 | 380 | 25 | 500 | 100 | 1102 | 180 | 450 | 400 | 180 | 245 | 30 | 305 | 530 | 450 | 4-ф24 |

| 160M-2/15 | 1290 | 225 | 840 | 600 | 1325 | 255 | 540 | 490 | 385 | 340 | 565 | 565 | ||||||||

| 160L-2/18.5 | 615 | 1370 | ||||||||||||||||||

| 180M-2/22 | 670 | 1395 | 285 | 430 | 590 | |||||||||||||||

| 80-50-315 | 112M-4/4 | 95 | 1140 | 210 | 740 | 400 | 125 | 500 | 100 | 1125 | 190 | 490 | 440 | 225 | 265 | 30 | 365 | 645 | 518 | 4-ф24 |

| 132S-4/5.5 | 1160 | 475 | 1200 | 210 | 315 | 548 | ||||||||||||||

| 180M-2/22 | 1290 | 225 | 840 | 670 | 1395 | 285 | 540 | 490 | 430 | 385 | 665 | 635 | ||||||||

| 200L-2/37 | 1420 | 250 | 940 | 775 | 1500 | 310 | 610 | 550 | 475 | 40 | 405 | 685 | 680 | 4-ф28 | ||||||

| 100-80-125 | 80-4/0.75 | 95 | 920 | 170 | 600 | 280 | 100 | 385 | 100 | 870 | 150 | 390 | 350 | 160 | 170 | 25 | 285 | 465 | 375 | 4-ф18.5 |

| 90S-4/1.1 | 310 | 895 | 155 | 190 | 385 | |||||||||||||||

| 90L-4/1.5 | 335 | 920 | ||||||||||||||||||

| 132S-4/7.5 | 1020 | 190 | 660 | 475 | 1060 | 210 | 450 | 400 | 315 | 30 | 468 | 4-ф24 | ||||||||

| 160M-2/11 | 1140 | 210 | 740 | 600 | 1185 | 255 | 490 | 440 | 385 | 300 | 480 | 525 | ||||||||

| 100-80-160 | 90L-4/1.5 | 95 | 1020 | 190 | 660 | 335 | 100 | 500 | 100 | 1035 | 155 | 450 | 400 | 160 | 190 | 30 | 285 | 485 | 385 | 4-ф24 |

| 100L-2/2.2 | 380 | 1080 | 180 | 245 | 430 | |||||||||||||||

| 160M-2/15 | 1290 | 225 | 840 | 600 | 1300 | 255 | 540 | 490 | 385 | 320 | 520 | 545 | ||||||||

| 100-65-200 | 100L-4/3 | 95 | 1140 | 210 | 740 | 380 | 100 | 500 | 140 | 1120 | 180 | 490 | 440 | 180 | 245 | 30 | 320 | 545 | 465 | 4-ф24 |

| 112M-4/4 | 400 | 1140 | 190 | 265 | 473 | |||||||||||||||

| 160M-2/15 | 1290 | 225 | 840 | 600 | 1340 | 225 | 540 | 490 | 385 | 340 | 565 | 565 | ||||||||

| 160L-2/18.5 | 645 | 1385 | ||||||||||||||||||

| 180M-2/22 | 670 | 1410 | 285 | 430 | 590 | |||||||||||||||

| 100-65-250 | 100L-4/3 | 110 | 1140 | 210 | 740 | 380 | 125 | 500 | 140 | 1145 | 180 | 490 | 440 | 200 | 245 | 30 | 340 | 590 | 485 | 4-ф24 |

| 112M-4/4 | 400 | 1165 | 190 | 265 | 493 | |||||||||||||||

| 132S-4/5.5 | 1160 | 475 | 1240 | 210 | 315 | 523 | ||||||||||||||

| 180M-2/22 | 1290 | 225 | 840 | 670 | 1435 | 285 | 540 | 490 | 430 | 360 | 610 | 610 | ||||||||

| 200L-2/37 | 1420 | 250 | 940 | 775 | 1540 | 310 | 610 | 550 | 475 | 40 | 380 | 630 | 655 | 4-ф28 | ||||||

| 100-65-315 | 132S-4/5.5 | 110 | 1270 | 225 | 840 | 475 | 125 | 530 | 140 | 1270 | 210 | 540 | 490 | 225 | 315 | 30 | 385 | 665 | 568 | 4-ф24 |

| 132S-4/7.5 | 515 | 1310 | ||||||||||||||||||

| 160M-4/11 | 600 | 1395 | 255 | 385 | 610 | |||||||||||||||

| 200L-2/37 | 1420 | 250 | 940 | 775 | 1570 | 310 | 610 | 550 | 475 | 40 | 405 | 685 | 680 | 4-ф28 | ||||||

| 225M-2/45 | 1620 | 290 | 1060 | 815 | 1610 | 345 | 660 | 600 | 530 | 425 | 705 | 730 | ||||||||

| 250M-2/55 | 930 | 1725 | 385 | 575 | 750 | |||||||||||||||

| 280S-2/75 | 1820 | 320 | 1200 | 1000 | 1795 | 410 | 730 | 670 | 640 | 785 | ||||||||||

| 125-100-200 | 112M-4/4 | 110 | 1140 | 210 | 740 | 400 | 125 | 500 | 140 | 1165 | 190 | 490 | 440 | 200 | 265 | 30 | 340 | 620 | 493 | 4-ф24 |

| 132S-4/5.5 | 1160 | 475 | 1240 | 201 | 315 | 523 | ||||||||||||||

| 132S-4/7.5 | 515 | 1280 | ||||||||||||||||||

| 180M-2/22 | 1290 | 225 | 840 | 670 | 1435 | 285 | 540 | 490 | 430 | 360 | 640 | 610 | ||||||||

| 200L-2/37 | 1420 | 250 | 940 | 775 | 1540 | 130 | 610 | 550 | 475 | 40 | 380 | 660 | 655 | 4-ф28 | ||||||

| 225M-2/45 | 815 | 1580 | 345 | 530 | 685 | |||||||||||||||

| 125-100-250 | 132S-4/5.5 | 110 | 1270 | 225 | 840 | 475 | 140 | 530 | 140 | 1285 | 210 | 540 | 490 | 225 | 315 | 30 | 385 | 665 | 568 | 4-ф24 |

| 132M-4/7.5 | 515 | 1325 | ||||||||||||||||||

| 160M-4/11 | 600 | 1410 | 255 | 385 | 610 | |||||||||||||||

| 200L-2/37 | 1420 | 250 | 940 | 775 | 1585 | 310 | 610 | 550 | 475 | 40 | 405 | 685 | 680 | 4-ф28 | ||||||

| 225M-2/45 | 1620 | 290 | 1060 | 875 | 1625 | 345 | 600 | 600 | 530 | 425 | 705 | 730 | ||||||||

| 225M-2/55 | 930 | 1740 | 385 | 575 | 750 | |||||||||||||||

| 280S-2/75 | 1820 | 320 | 1200 | 1000 | 1810 | 410 | 730 | 670 | 640 | 785 | ||||||||||

| 125-100-315 | 160M-4/11 | 110 | 1270 | 225 | 840 | 600 | 140 | 530 | 140 | 1410 | 255 | 540 | 490 | 250 | 385 | 30 | 410 | 725 | 635 | 4-ф24 |

| 160L-4/15 | 1420 | 250 | 940 | 645 | 1455 | 610 | 550 | 40 | 430 | 745 | 655 | 4-ф28 | ||||||||

| 280S-2/75 | 1820 | 320 | 600 | 1000 | 1810 | 410 | 730 | 670 | 640 | 450 | 765 | 810 | ||||||||

| 280M-2/90 | 1020 | 1860 | ||||||||||||||||||

| 315S-2/110 | 1190 | 2000 | 460 | 800 | 740 | 760 | 895 | |||||||||||||

| 125-100-400 | 160L-4/15 | 130 | 1620 | 290 | 1060 | 645 | 140 | 530 | 140 | 1455 | 255 | 660 | 600 | 280 | 385 | 40 | 480 | 835 | 705 | 4-ф28 |

| 180M-4/18.5 | 670 | 1480 | 285 | 430 | 730 | |||||||||||||||

| 180L-4/22 | 710 | 1520 | ||||||||||||||||||

| 200L-4/30 | 775 | 1585 | 310 | 475 | 755 | |||||||||||||||

| 150-125-250 | 160M-4/11 | 110 | 1270 | 225 | 840 | 600 | 140 | 530 | 140 | 1410 | 255 | 540 | 490 | 250 | 385 | 30 | 410 | 765 | 635 | 4-ф24 |

| 160L-4/15 | 1420 | 250 | 940 | 645 | 1455 | 610 | 550 | 40 | 430 | 785 | 635 | 4-ф28 | ||||||||

| 180M-4/18.5 | 670 | 1480 | 285 | 430 | 680 | |||||||||||||||

| 150-125-315 | 180M-4/18.5 | 130 | 1620 | 290 | 1060 | 670 | 140 | 530 | 140 | 1480 | 285 | 660 | 600 | 280 | 430 | 40 | 480 | 835 | 730 | 4-ф28 |

| 180L-4/22 | 710 | 1520 | ||||||||||||||||||

| 200L-4/30 | 775 | 1585 | 310 | 475 | 755 | |||||||||||||||

| 150-125-400 | 200L-4/30 | 130 | 1620 | 290 | 1060 | 775 | 140 | 530 | 140 | 1580 | 310 | 660 | 600 | 315 | 475 | 40 | 515 | 915 | 790 | 4-ф28 |

| 225S-4/37 | 820 | 1630 | 345 | 530 | 820 | |||||||||||||||

| 225M-4/45 | 845 | 1655 | ||||||||||||||||||

| 200-150-250 | 180L-4/22 | 130 | 1620 | 290 | 1060 | 710 | 160 | 530 | 180 | 1580 | 285 | 660 | 600 | 280 | 430 | 40 | 480 | 855 | 730 | 4-ф28 |

| 200L-4/30 | 775 | 1645 | 310 | 475 | 755 | |||||||||||||||

| 225M-4/37 | 820 | 1890 | 345 | 530 | 785 | |||||||||||||||

| 200-150-315 | 200L-4/30 | 130 | 18200 | 320 | 1200 | 775 | 160 | 670 | 180 | 1785 | 310 | 730 | 670 | 315 | 475 | 40 | 515 | 915 | 790 | 4-ф28 |

| 225S-4/37 | 820 | 1830 | 345 | 530 | 820 | |||||||||||||||

| 225M-4/45 | 745 | 1855 | ||||||||||||||||||

| 250M-4/55 | 930 | 1940 | 385 | 575 | 840 | |||||||||||||||

| 200-150-400 | 225N-4/45 | 130 | 1840 | 320 | 1200 | 845 | 160 | 670 | 180 | 1855 | 345 | 730 | 670 | 315 | 530 | 40 | 515 | 965 | 820 | 4-ф28 |

| 250M-4/55 | 930 | 1490 | 385 | 575 | 840 | |||||||||||||||

| 280S-4/75 | 1000 | 2010 | 410 | 640 | 875 | |||||||||||||||

| 280M-4/90 | 1050 | 2060 |

pump setting

The quality of pump installation has a significant impact on the operation and service life of the pump, so installation and calibration must be carried out carefully, including the appearance and installation dimensions of the pump

1. Installation and calibration:

(1) Remove the grease and dirt from the base and place it on the foundation.

(2) Check the levelness of the base with a spirit level and allow for leveling with a wedge iron.

(3) Pour cement into the base and anchor bolt holes.

(4) After the cement dries up, check whether the base and anchor bolt holes are loose, tighten the anchor bolts if they are suitable, and recheck the levelness.

(5) Clean the support plane of the base, the plane of the water pump foot and motor foot, and install the water pump and motor onto the base.

(6) A certain gap should be maintained between the couplings, and the centerline of the water pump shaft and motor shaft should be checked for consistency. Thin gaskets can be used to adjust them to be concentric.

The difference between the outer circumference of the coupling should not exceed 0.1mm, and the maximum and minimum gap difference between the end faces of the two couplings should not exceed 0.3mm.

2. Installation instructions:

(1) The installation height of the pump, the length, diameter, and flow rate of the pipeline should comply with the calculation, striving to reduce unnecessary losses.

(2) When transporting over long distances, a larger diameter should be used, and the pump pipeline should have its own support. The weight of the pipeline should not be added to the pump to avoid damaging it.

(3) If a check valve is installed in the discharge pipeline, it should be installed outside the gate valve.

IS clear water centrifugal pump, IR hot water centrifugal pump